Research Article

Creative Commons, CC-BY

Creative Commons, CC-BY

Invention and Verification Based on Self-Propelled Electric Seeder for Tea Plant

*Corresponding author: Luofa Wu, Institute of Agricultural Engineering, Jiangxi Academy of Agricultural Sciences, Nanchang, China.

Received: April 03, 2024; Published: April 15, 2024

DOI: 10.34297/AJBSR.2024.22.002921

Abstract

To solve the problems of insufficient sowing equipment, low sowing efficiency, and poor sowing uniformity of tea plants, a self-propelled electric tea plant seeder was authorized by a Chinese patent (ZL202310665671.9) and made a prototype. The key structure of the planter was designed based on the physical characteristics of the tea seeds and the agronomic requirements of tea planting, and the structural parameters were determined. The motor and battery configurations are determined by calculating the power consumption of the entire machine. In the field experiment, the driving gear (A), Ditching Depth (B), and planting gear position (C) were used as test factors, and the Acceptance Index (AI), Replay Index (RI) and Leakage Index (LI) are used as test indexes. The test results showed that the driving speed and planting gear position significantly affected the acceptance index, replay, and leakage index, whereas the ditching depth had little effect on the performance indices. When the driving speed was medium, the ditching depth was 30 mm, and the planting gear position was in the third gear, with a corresponding acceptance index of 87.22%, replay index of 8.89%, and leakage index of 3.89%. The test prototype has good working quality and can provide theoretical guidance for production practices.

Keywords: Tea seed, Electric, Planter, Orthogonal test

Introduction

Tea is one of the three major beverages consumed worldwide. Approximately 71.4 percent of the world’s countries and regions and approximately one-third of its population drink tea. Tea was originally produced in China and has been grown and consumed for more than 5,000 years. Tea cultivation is mainly distributed in tropical and subtropical regions worldwide, with a tea cultivation area of 3.165 million hectares in China, accounting for 62.1% of the total tea cultivation area worldwide, ranking first in terms of tea cultivation [1]. According to a report by the General Station of Agricultural Mechanization of China's Ministry of Agriculture and Rural Affairs, in 2021, tea garden cultivation, fertilization, plant protection, pruning, harvesting, and field transport mechanization rates were 22%, 11%, 35%, 43%, 35%, and 36%, respectively. The comprehensive mechanization rate was approximately 31.15%. The mechanization level of each link is not high, and tea production mechanization is how China’s tea industry develops. However, we believe that this statistical analysis misses the most important link in tea production, mechanized planting. Mechanized planting is not only related to intervillage, fertilization, plant protection, pruning, harvesting, and field transfer, but mechanized tea garden operations can also result in smooth development and directly affect the quality and yield of tea. Hence, mechanized tea planting (including breeding and transplanting) is a key component of mechanized tea production. Tea breeding methods include sexual, asexual, and transgenic cultivations. Sexual propagation uses seeds to propagate the tea seedlings. Tea seedlings have deep soil, well-developed taproots, high survival rates, and strong drought and cold resistance [2].

Sexual reproduction can result in greater genetic variation, which is critical for cultivation of improved tea varieties. Asexual propagation is mainly conducted via cutting, which is widely used in the large-scale breeding of fine tea varieties to realize the rapid promotion and planting of superior varieties. However, asexual propagation faces the problem of rapid loss of some gene sources that have not been recognized and used [3]. Transgenic cultivation via genetic engineering has been used to improve tea trees, tea yield, and insect resistance. Currently, this technology is still in the development and research stages, and its commercial application faces many controversies and challenges [4]. Based on a comparison of the results of the above three methods, some scholars believe that the cultivation of improved tea varieties mainly depends on sexual reproduction [5], that is, using tea seeds to sow and raise seedlings. Currently, tea seedlings are mainly artificial and lack devices that meet the requirements of tea seed planting agronomy, leading to low work efficiency, high labor costs, and lack of sowing uniformity. Hence, research and development are required for tea sowing machinery to improve tea seed planting efficiency and sowing quality, reduce the labor intensity of tea seed sowing, and improve production. Many scholars have conducted in-depth research on sowing devices and developed practical sowing machinery [6-8]. Based on the shape characteristics of garlic, Wenyuan [9] developed a hole-wheeled garlic seeder. A field test showed that it had a good seeding effect, with a qualified rate of 88.44%, missing sowing index of 7.44%, and replay index of 4.11%. Zolha, et al., [10] studied the effects of different operational parameters on maize-seeding devices. The study showed that the hole shape, peripheral velocity, vacuum pressure, and hole area had significant effects on seeding. The optimal shape of the seed hole was rectangular, the seed holding rate decreased with an increase in the velocity around the seed plate, and the seed holding rate increased with an increase in vacuum pressure.

Ozherelyev, et al., [11] analyzed the causes of spatial orientation instability of potato tubers during seed selection using dynamic theory and optimized a prototype, achieving a qualified potato tuber orientation rate of more than 97%. Yitao, et al., [12] analyzed the seed discharge process of a seed discharge device by combining theoretical analysis with high-speed camera technology, identified the factors affecting the seed discharge track of the device, and provided a basis for optimizing the structural design of the device. Yoxia [13] and Mengmeng [14] studied the effect of vibration on seeding performance from the vibration direction, and the results showed that the replay rate tended to decrease and that the missed sowing rate tended to increase with an increase in vibration frequency and vibration amplitude. Other scholars [15-17] have studied the seed spoon of a seeder using discrete element simulation and response surface optimization methods to obtain better structural parameters for the seed spoon and improve the seeding effect of the seeder. Lu Yao, et al., [18] adopted an orthogonal test method to analyze the effects of the advance speed, seed-casting angle, and seed-casting height of a corn planter on the seeding performance and obtained a better parameter range. The field experiment showed that the qualified seed spacing rate was greater than 95%, single-seed rate was greater than 90%, and hole rate was less than 5%. Based on the research conclusions and methods of the above scholars, combined with the physical and mechanical characteristics of tea seeds and agronomic characteristics of planting, we invented a self-powered electric tea seeder, obtained authorization from the Chinese State Intellectual Property Office (ZL202310665671.9), manufactured the prototype, and carried out the corresponding test. Through experimental optimization methods, we expect to obtain better operation parameters for the seeder, achieve a better seeding effect, and promote the development of mechanized tea-seeding planting technology.

Materials and Methods

Measurement of the Physical Parameters of Tea Seeds

Seed size, shape, weight, and surface characteristics significantly affect seeder performance. Therefore, we investigated the physical and mechanical characteristics of tea seeds.

Size Measurement of Tea Seed: The shapes and sizes of tea seeds have a significant influence on the filling of the seed spoon and the fluidity of the seeds in the seed box. Therefore, it is necessary to determine the size and shape of tea seeds. Under normal circumstances, the surface of a tea seed is smooth, and the shaped structure can be regarded as an ellipsoid. We used a wide diameter La and long diameter Lb to describe the outline sizes of the seeds, as shown in Figures (1a,1b).

To understand the shape and size distribution of tea seeds, two different tea seeds (Normal 1 and Extra Early 1) were selected, and 400 seeds were randomly sampled and measured with a Vernier caliper (range of 300mm, precision of 0.02mm). Figure 2 shows a histogram of the size-frequency distribution. From the perspective of the major diameter size distribution, the size of Normal 1 was mainly distributed in the range of 10-17mm and the size of Extra Early 1 was mainly distributed in the range of 10-16mm. Both showed a myopically normal distribution. From the perspective of broad diameter size distribution, the normal 1 broad diameter size was mainly distributed in the range of 11-17mm, and the broad diameter size of Extra Early 1 was mainly distributed in the range of 10-16mm. Again, both were normal myopic distributions. In summary, more than 90% of the major and broad diameters of the two types of tea seeds were distributed in the range 10-16mm (Figure 2a, 2b).

Figure 2: Size distribution of the two tea seeds. (a) Major diameter size distribution, (b)Broad diameter size distribution.

Hundred Grain Weight and Water Content Measurement: Seed weight had some influence on the stability of the charging and seed carriage of the seed arrangement device. For example, for a chain-spoon-type seed distributor, the seed weight is too low, and the instability of the filling and carrying processes increases, which reduces sowing accuracy. For Normal 1 and Extra Early 1, 100 tea seeds were randomly selected, and the tea seeds were weighed using an electronic scale (LD510-2, accuracy of 0.01g, Shenyang Longteng Electronics Co., Ltd.). The corresponding weights were recorded five times. The average hundred grain weight of Normal 1 was 105.52g, and that of Extra Early 1 was 108.73g. The seed moisture content is an important indicator of seed quality. Seeds with a high moisture content are not easy to store, as the adhesion between seeds becomes large, which affects the seeding accuracy of the seed discharging device. When the moisture content of the seeds is too low, their physiological activity is affected. In this study, the constant-temperature drying method was used to determine the water content specified by the national standard GB5009.3-2016 "Determination of Water in National Standard of Food Safety.” A drying oven (HD-E804-60A, accuracy of ±1 ℃, Haida International Instrument Co., Ltd.) was used to bake the two types of tea seeds (five parts each), and the weight before and after baking was measured using an electronic scale. The water content of each sample was calculated using the following formula: After taking the average value, the water content of the Normal 1 tea seeds was 17.38%, and that of the Extra Early 1 tea seeds was 15.47%, which met the commonly used water content requirements for seed storage [19].

Structure and Key Components

Combining the physical and mechanical characteristic parameters of tea seeds and the agronomic requirements of tea planting, we designed a self-propelled electric tea seed planter and expounded the working principle of the tea seed planter.

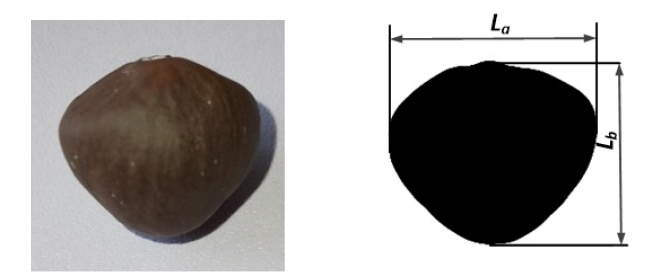

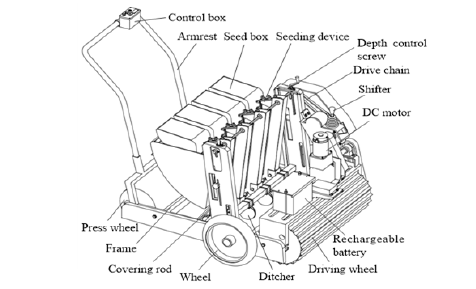

Structure and Principle: A self-propelled electric tea seed planter is primarily composed of frames, ditchers, seeding devices, shifters, drive wheels, seed boxes, press wheels, DC motors, and rechargeable batteries, as shown in Figure 3. The seed box, seeding device, and ditcher were assembled into a single body to form the trenching-seeding unit. When preparing for seeding, the shifter was adjusted from the neutral position to the forward gear, the walking switch on the control box was dialed, and power was delivered to the driving wheel through the chain to drive the entire machine to walk. As the seed planter walks, the ditcher marks the seed ditch at the same depth on the ridge surface and the seeding device drives the tea seeds out of the seed box via another transmission branch to accurately place them into the seed ditch. Soil particles were then backfilled to the seed ditch under the action of a soil-covering rod to cover the seeds. Finally, the soil suppression was completed using the suppression wheel. During the operation, the machine can simultaneously achieve ditch opening, sowing, and suppression at one time. While completing the operation, the shifter was adjusted to a neutral position to cut off the driving power to ensure that the machine did not sow. The overall parameters of the self-propelled electric tea seed planter according to the agronomic requirements of tea seed sowing are listed in Table 1 (Figure 3).

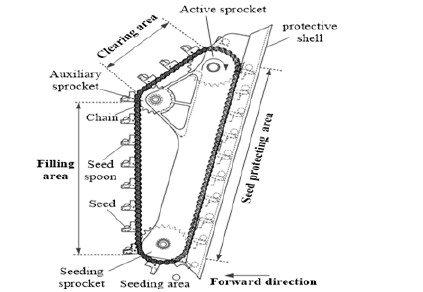

Structure of Seeding Device: The chain-spoon-type precision seeding device used in this study is a single-row monomer-type seeding device that includes an active sprocket, auxiliary sprocket, chain, seed spoon, seeding sprocket, and seed-protection shell, as shown in Figure 4. Combined with the size distribution area of the tea seeds, seed spoons were selected from existing market products. The major diameter of the seed spoon hole was 20mm, the broad diameter was 16mm, and the depth was 6 mm, ensuring that the seed-filling process of the seed spoon hole contained only one tea seed. The seed trap can be divided into four areas: the filling, clearing, seed protection, and casting areas, among which the filling area is in the seed box. During the operation of the seeding device, power is input by the active sprocket, which drives the chain to rotate clockwise. As the seed spoon enters the filling area, the seeds fall into the seed spoon to complete the filling under the weight of the seeds and the inter-seed forces. As the chain continued to rotate, the seed spoon left the filling area and entered the clearing area. Redundant seeds that may exist in the seed spoon leave the spoon under the action of gravity and chain vibration to ensure that only a single seed is retained in the spoon. The seed spoon continues to move upward with the chain, and when it passes the highest point of the active sprocket, it breaks away from the seed spoon-type hole and falls on the bottom of the previous seed spoon under the action of gravity and centrifugal force to enter the seed-protecting area. In the seed-protecting area, the seeds remain in an independent space formed by the two seed spoons and seed protection shell. They then entered the seed-casting area with the movement of the chain. In the casting area, when the sliding force of the seed was greater than the maximum static friction force, the seed slid away from the bottom of the seed spoon and fell into the seed ditch to achieve seeding. The spoon then turns around the sprocket and re-enters the filling area, thereby entering the next cycle and continuing to complete the seeding operation (Figure 4).

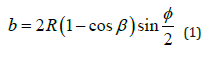

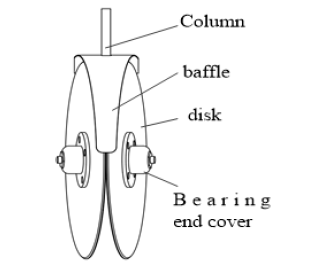

Structure of the Ditcher: A double-disc ditcher is used in this study. As a key component of a planter [20], its structure mainly includes columns, baffles, disks, and bearing end covers, as shown in Figure 5. The two disks at the front end of the ditcher intersect at convergence point m. The angle between the convergence point position and the plumb weight direction is β, and the angle between the two disks is ∅, as shown in Figure 6. According to [21], the following relationship is satisfied between the parameters:

where

b=trench width(mm),

R=disc radius(mm).

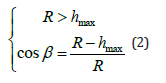

According to the formula above, the trench width increases with an increase in the diameter and angle of the disk. For a double-disc ditcher, a large trench width can easily cause an increase in the middle bulge of the groove, which adversely affects seeding. Additionally, the common double-disc angle ∅ is 9-16°. The higher the location of the convergence point, the greater the angle β and the width of the trench will increase, meaning that the high location of the convergence point will cause the width of the trench to be larger. In the actual selection, the value of β ranged from 55° to 75°. In the design, the diameter of the disc, selection of the convergence point, and size of the angle between the two discs should be determined according to the agronomic requirements of actual sowing (Figure 5&6). According to the agronomic requirements of tea seed sowing, the sowing depth should be 30-50mm [22]. We selected a double disc with a diameter of 200mm. According to Equation (2), the disk radius is greater than the maximum trench depth, which satisfies the design requirements. The calculated results showed that the angle β of the convergence point position was 67.97°. Finally, β was rounded off to 68°.

where

hmax=Maximum trench depth(mm).

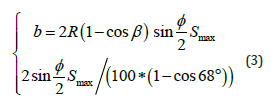

Considering that ditching quality has a significant influence on tea seed sowing, the ditching width of a double-disc ditcher should not be too large [23]. To ensure that the tea seeds fall smoothly into the seed ditch, the opening width should be greater than the seed size limit, as shown in Equation (3).

where

Smax=Limit size of tea seeds.

We take Smax=16mm. According to Eq. (3), the angle between the two disks must satisfy ∅>14.70°. Finally, ∅ is rounded to 15°. Furthermore, according to Equation (1), trench width b was 16.3mm.

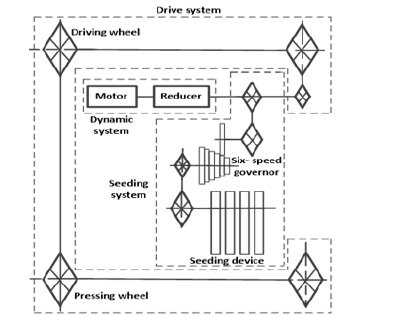

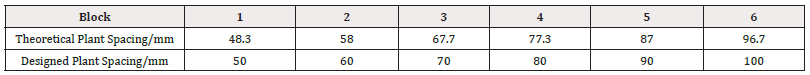

Design of Transmission System: Unlike other types of seed planters [24,25], the tea seed planter used in this study is driven by a motor. The entire transmission system can be roughly divided into power, driving, and seeding systems, as shown in Figure 7. The transmission of motion between systems is realized through chain transmission (Figure 7). Considering the different needs of seeding spacing, a special six-speed governor of the planter produced by Pengfeng Company was set in the seeding system. The governor’s input gear teeth were 18, and the output teeth were 15, 18, 21, 24, 27, and 30. The corresponding six gear transmission ratios are 0.833, 1, 1.167, 1.134, 1.5, and 1.667, respectively. During the design, the driving and seeding systems are driven by the same power system, and the transmission ratio of the driving system and seeding system are calculated to simultaneously obtain the driving distance of the driving wheel and the number of spoons involved in the seeding. The sowing distance for different gear positions can be obtained by comparing the two values, as shown in Table 2.

Power Calculation and Battery Selection

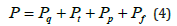

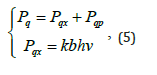

i. Power Calculation: The operation of a tea seed planter must overcome trenching, driving, soil covering, and transmission friction resistance. In this process, the power consumed to overcome the trench and the driving resistance accounts for more than 80% of the total power consumption of the system. The power consumption of the system satisfies the following relationship:

where P is the total power, Pq is the trench power consumption, Pt is the forward-driving power consumption, Pp is the power consumption of the soil cover, and Pf is the transmission friction power consumption. Considering that the soil cover and transmission friction resistances were small, the driving power consumption of the trenching power and driving power consumption were analyzed empirically in the power calculations. During the ditching operation, the power consumption of the double-disc ditcher mainly originates from the disc cutting and disc-throwing soils [26]. The power consumption satisfies the requirements shown in (5). Moreover, the trench tray of the tea seed planter was rotated passively while driving; the maximum speed of the tray did not exceed 100r/min, and the soil throwing effect of the disc was weak. Therefore, the trench operation primarily considers the power consumption of the tray-cutting soil.

where

Pqx=cutting soil power consumption (kW),

Pqp=Disc throwing power consumption (kW),

k=cut specific resistance (kN/m2),

b=trench width (mm),

h=trenching depth (mm),

v=planter forward speed (m/s).

According to the relevant research [26], we take k=137kN/m2, b=16.3mm, and h=50mm. The maximum speed of the seeder driving forward is assumed to be v=1m/s. The power consumption of a single trench opener of the tea seed planter is 0.11kW, and the total power consumption of the trench opener is 0.44kW.

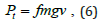

Rolling resistance is the main source of power consumption during the planter operation. The forward power consumption of the entire machine satisfies the following relationship.

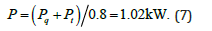

where f denotes the rolling friction factor, m is the machine weight(kg), and v denotes the forward speed of the seeder (m/s). The soil resistance in the tea garden was relatively large, and the rolling friction factor was set to 0.4. The weight of the entire machine is 95kg, and the maximum forward speed of the seeder is 1m/s, meaning that the forward power consumption of the entire machine is 0.38kW. Considering that power consumption, accounting for the transmission friction and soil-covering resistance of the seeder, accounts for approximately 20% of the total power consumption, the total amount of power required by the tea seed planter is 1.02kW (Equation (7)). Considering the possibility of an uneven ground surface and a large soil viscosity during the operation process, and given a power reserve coefficient of 1.5, the resulting total design power is 1.53kW. Based on these calculations, we chose a brushless DC motor produced by the Taili Company of Sanmen County to provide power with a rated voltage of 24 V, maximum output power of 1.5kW, and a rated speed of 1800r/min. Furthermore, the reduction ratio of the reducer directly connected to the output end of the motor was 1:60.

i. Battery Selection

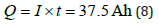

Based on the cost, battery density, and environmental adaptability, seven lead batteries (produced in series (24 V) by Dongguan Youneng Optoelectronics Co., Ltd.) were used as the power sources for the tea seed planter. Assuming that the seeder works at the rated speed of the motor, the seeder will perform seeding at a driving speed of 0.15m/s. Its power consumption is calculated as 0.15 kW, according to Equations (4)-(7). For the DC motor, the required driving motor current I=6.25 A was obtained. Assuming that the planter operates for 6 h per day, the required capacity Q for the battery is:

Considering that tea seed sowing is mostly conducted in autumn and winter, the outdoor temperature is low at this time, which has an impact on battery capacity consumption. Therefore, the battery capacity consumption must be corrected [27]:

where

Qx=Fixed battery capacity consumption (Ah),

I=Maximum discharge current (A),

T=Total discharge time,

ƞ=Modified battery capacity,

t=Actual temperature (℃).

We set I=5 A, T=6h, ƞ=0.917, and t=10 ℃. By inserting these parameters into the formula, we obtained Qx=46.47Ah, which is less than the total battery capacity of 50Ah. This indicates that the selected lead battery can satisfy the requirements of sowing work under these temperature conditions.

Test Equipment and Materials

The test equipment included a self-developed seed planter, soil moisture measuring instrument (Model: TZS-I, Zhejiang Topu Instrument Co., Ltd., Zhejiang, China; measuring range of 0-99.9%; accuracy of ±2%), ruler (Guangzhou Qiyike Industrial Development Co., Ltd., Guangzhou, China; measuring range of 0-500 mm; accuracy of 1 mm), and steel measuring tape (Ningbo Great Wall Seiko Industrial Co., Ltd., Zhejiang, China; measuring range of 0-100m, accuracy of 1mm). The test site was located in the “Tea Full Mechanization Research Base” of the Xiangcheng Town Ministry of Agriculture and Rural Affairs, Gao'an City, Jiangxi Province, China. The average soil moisture content was 22.43% (Figure 8).

Evaluation Index and Experimental Design

Evaluation Index: Based on the standard GB/T 6973-2005 “Test Method for Single Seed (Precision) Planter” [28] and the test outline DG/T 007-2019 “Planter” [29], the experimental research was carried out, and the acceptance index (AI), Replay Index (RI), and Leakage Index (LI) were taken as the evaluation indexes of the economy, reliability, and adaptability. The corresponding indices are calculated as follows:

where

n′i is the frequency of grain (hole) distance in each section,

ni is the frequency of grain (hole) distance,

Xi is a segment variable with a segment length of 0.1Xr,

xi is the median value of the section (mm),

Xr is the theoretical particle (hole) distance (mm),

N is the total number of particles (holes) determined by the test,

N’ is the number of intervals.

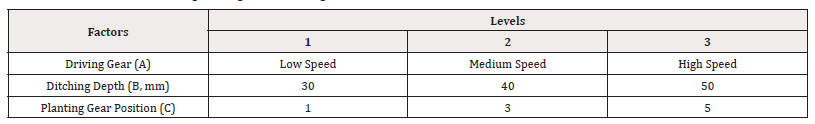

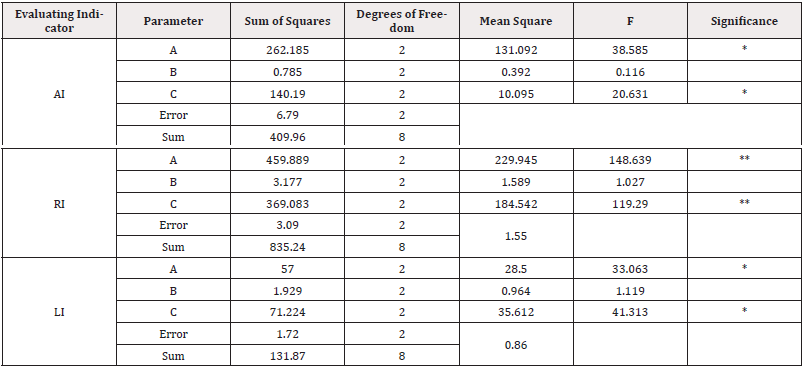

Experimental Design: Through a preliminary experiment, it was found that the operational stability of the entire machine was different for different driving gears. A high driving speed reduces stability but increases the vibration of the entire machine, and a low driving speed reduces seeding efficiency. Therefore, we consider driving gear (A) to be an influencing factor at low, medium, and high speeds. As an area of direct contact with seeds, the seed trench may have an effect on sowing. Considering that the sowing depth of tea seeds is 30-50mm, the ditching depth (B) is also an influencing factor, and three ditching depths of 30, 40, and 50mm were selected. The higher the gear, the faster the seeding speed. The planting gear position (C) was also considered an influencing factor, and three gear levels (1, 3, and 5) were selected for the experiment. To explore the influence of each factor on the sowing effect and obtain an ideal combination of test parameters, three-factor and three-level orthogonal test methods were adopted and applied to the L9(34) orthogonal table design test to analyze the effects of multiple parameter changes on the performance of the seeder to provide a technical basis for the next promotion. The test factor levels are listed in Table 3 (Table 3).

Results

Orthogonal assistant design software was used to generate the test schedule, conduct field tests according to the field test process and evaluation index calculation methods, and record test data. The Acceptance Index (AI), Replay Index (RI), and Leakage Index (LI) were calculated for different test parameter groups according to Equation (10), and the test results were analyzed using orthogonal software. The orthogonal test table and test results are listed in Table 4.

Polar Difference Analysis

The test results were analyzed, and polar difference analysis was used to analyze the degree of influence of each factor on the evaluation index at different levels. The greater the polar difference (R value), the greater the influence of the factor-level change on the evaluation index. Table 5 shows the results of the differential analysis of the Acceptance Index (AI), Replay Index (RI), and Leakage Index (LI) (Table 5).

For the Acceptance Index (AI), the driving speed (A) had the greatest impact, followed by the planting gear position (C), whereas the ditching depth (B) had little impact. The best parameter combination for the Acceptance Index (AI) is A2B3C2. The reasons for these results are as follows: With an increase in driving speed (A), the vibration and jitter of the whole machine increase, which is conducive to the cleaning of the spoon, which can reduce the replay situation and thereby improve the qualified rate. However, if the driving speed is too high, the leakage situation increases, thereby reducing the qualification rate. With an improvement in the planting gear position (C), the seeding rate and interactions between the seeds increased, which was beneficial for clearing the seeds, reducing the replay rate, and improving the qualified rate. However, with a further increase in the planting gear position (C), the seed spoon becomes late in supplementing the seeds, and the chain vibration can increase the leakage, thereby reducing the qualified rate. For the Replay Index (RI), the most significant impact is the driving speed (A), followed by the planting gear position (C) and ditching depth (B). The best parameter combination for the Replay Index (RI) is A3B3C3. This is because with the increase in driving speed (A), the vibration and jitter of the entire machine increase, which is conducive to cleaning the spoon and can reduce the replay rate (RI). However, with an increase in the planting gear position (C), the seeding rate, interaction between the seeds, and speed and vibration of the seed chain all increased, which was conducive to seed clearing and reducing the replay rate (RI).

For the Leakage Index (LI), the greatest influence is on the planting gear position (C), followed by the driving speed (A). The ditching depth (B) is less influential. The best parameter combination for the leakage index (LI) was A1B2C1 for the following reasons. With an increase in the planting gear position (C), the planting rate increased. However, with an increase in the driving speed (A), the vibration and jitter of the entire machine increase, which is conducive to the cleaning of the seeds and may also cause increased leakage.

Ditching depth (B) had little influence on the three evaluation indicators. The reason for this may be that when adjusting the trench depth, the relative positions of the ditcher and seeding device do not change, meaning that the seed falling height is relatively fixed. Thus, ditching depth had little influence on the sowing effect.

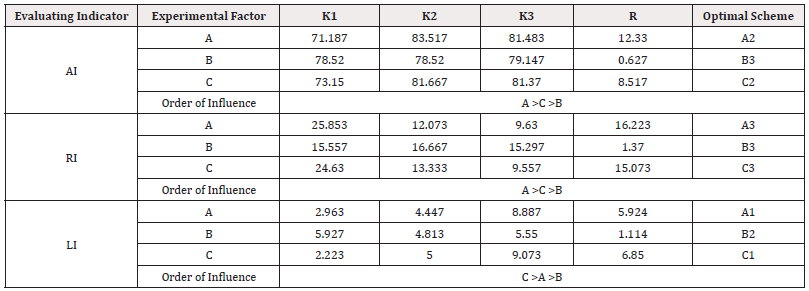

Significance Analysis

To study the degree of influence of each factor on the evaluation index, we performed an analysis of variance for each evaluation index. The results are presented in Table 6.

Note*: a. When P<0.01, the result is extremely significant and is symbolized with “**”. When P<0.05, the result is significant and is symbolized with “*”.

According to Table 6, the driving speed (A) and planting gear position (C) have significant effects on the Acceptance Index (AI), Replay Index (RI), and Leakage Index (LI). The influence of the opening depth (B) on the index parameters was insignificant. The order of significance of the influence of each factor on the Acceptance Index (AI), and the Replay Index (RI) is A, C, and B. The significant order of the effect of each factor on the Leakage Index (LI) is C, A and B. According to Equation (10), the requirements for the acceptance, replay, and leakage indices are AI+RI+LI=1. The planter seeding Acceptance Index (AI) should be increased and the Replay Index (RI) and Leakage Index (LI) should be reduced. According to the analysis above, the optimal parameter combination of the three evaluation indicators is inconsistent. Hence, we used the Acceptance Index (AI) as the core evaluation index to further analyze the working performance of the prototype.

Validation Test

According to polar difference analysis, the best parameter combination for the Acceptance Index (AI) is A2B3C2. Considering that ditching depth (B) had no significant influence on any indicator, we conducted a validation test, as shown in Table 7. Comparing the test results with the test combinations listed in Table 4 (i.e., A2B1C2, A2B2C2, and A2B3C2), the Acceptance Index (AI) was above 87%, whereas the Replay Index (RI) and Leakage Index (LI) were lower, further verifying that the ditching depth (B) did not have a significant influence on any index (Table 7).

Discussion

1) From the test results, the replay index of the tea seed sowing of the test prototype was approximately 8%, and the leakage index was approximately 4%, which is somewhat high, indicating that the sowing effect can be further improved. The possible reasons for this are as follows. First, the test was carried out in an outdoor tea garden, and the changes in terrain and soil conditions may have increased the vibration of the entire machine and affected the sowing effect. Second, the prototype adopted different driving gears, and its optimal working state may not be the test combination recommended by the orthogonal test. Third, the prototype seed spoon was purchased from the market, considering only the size of the seed-spoon hole; we did not study the impact of other factors in depth.

2) As a key component of the seed planter, the material, dimensions, and shape characteristics of the seed scoop may influence seed-taking. In the future, the research team will conduct a theoretical analysis of the contact and friction between the tea seeds, seed spoon, and arc of the shaped hole of the seed spoon to further explore the influence of the structure and material of the seed spoon the seed-taking effect using numerical simulations.

3) The environment affects the seeding effect on the seed planter. For example, the seeding effect was significantly different under different soil types and humidity conditions. Therefore, research on an appropriate environment for seedling is a problem that must be considered in the application and promotion of seed planters.

Conclusion

1) The physical and mechanical parameters of the tea seeds were determined, and two different types of tea seeds (Normal 1 and Extra Early 1) were selected for size measurements. The measurement results showed that the major and broad diameters of the tea seeds were normally distributed, with a size distribution in which over 90% of the measurements fell between 10 and 16 mm. For Normal 1, the average hundred grain weight and water content were 105.52g and 17.38%, respectively. For Extra Early 1, the average hundred grain weight and water content were 108.73g and 15.47%, respectively.

2) We invented a self-powered electric tea seeder, obtained the authorization of the Chinese State Intellectual Property Office (ZL202310665671.9), manufactured the prototype, and carried out a corresponding test to simultaneously perform ditching, seeding, soil covering, suppression, and other operations. Core components such as the seeding device, ditching device, and transmission system were designed and analyzed. After analysis, a chain-spoon-type precision seed feeder was selected. The major diameter of the seed-spoon hole was 20mm, broad diameter was 16mm, and depth was 6mm. A double-disc ditcher is used in this study. By calculation, the diameter of the disc was 200mm, angle β of the convergence point of the disc was 68°, and angle of the double disc was 15°. The transmission system of the machine was designed to achieve an adjustable range of 50-100mm. The power of the entire machine was calculated, and the total power of the tea seed planter was 1.02kW. The 1.5kW DC motor and 24V (50Ah) battery were matched.

3) In the prototype test, the orthogonal test method was used to analyze the effects of driving speed, ditching depth, and planting gear position on the working performance of the tea seed planter. The test results showed that the driving speed and planting gear position significantly affected the acceptance, replay, and leakage indices, whereas the ditching depth had little effect on the operational performance of the tea seed drill. The orthogonal test results showed that when the driving speed was moderate, the ditching depth was 30mm, planting gear position was 3, corresponding acceptance index was 87.22%, replay index was 8.89%, and leakage index was 3.89%. The influence on the ditching depth was further verified in the case of the medium-speed gear and three planting gear positions. The experimental results showed that the receiving index exceeded 87%, the replay and leakage index changed little, and the invention was very effective.

Acknowledgements

None.

Conflict of Interest

None.

References

- Wu L, Shu S, Xu G, Ye C, Wu Y (2023) Analysis on the technical gap and key problems of tea picker in China. Significances Bioeng Biosci 6(1): 1-6.

- Yang S, Yi B, Zhang J (2010) Technology of tea seed rearing in Yunnan large leaf tea. Yunnan Agric Sci Technol 01: 33-34.

- Zhou J, Liu Z (1992) Research progress of tea plant genetics and breeding. J Tea 02: 17-22.

- Chen H, Lu J, Zheng X, Liang Y (2010) Advances in breeding and cultivar multiplication of tea since 2000. J Tea 36: 6-9.

- Liang Y, Shi M (2015) Advances in tea plant genetics and breeding. J Tea Sci 35(2): 103-109.

- Guo J, Zhao W, Shi L, Zhou G, Zhang F, et al. (2022) Design and test of rolling spoon type flax combined seeder in the arid area of northwest China. J China Agric Univ 27(7): 184-198.

- Cui R, Wang X, Xin J, Sun L, Wu C (2022) Design and test of arc duck-billed garlic seed planter. Trans Chin Soc Agric Mach 53: 120-130.

- Panning JW, Kocher MF, Smith JA, Kachman SD (2000) Laboratory and field testing of seed spacing uniformity for sugar-beet planters. Appl Eng Agric 16(1): 7-13.

- Song W (2020) Design and Experimental Study on Key Components of Garlic Seeder [Master’s Thesis]. Northwest A and F University.

- Barut ZB, Ozmerzi A (2004) Effect of different operating parameters on seed holding in the single seed metering unit of a pneumatic planter. Turk J Agric For 28(6): 435-441.

- Ozherelyev VN, Kotikov FN (2017) Sprouted potato tuber dynamics and kinematics during mechanized planting. Procedia Eng 206(2017): 56-60.

- Liao Y, Li C, Liao Q, Zhang B, Zheng J, et al. (2022) Design and experiment of narrow-row-dense-planting precision planter for American ginseng. Trans Chin Soc Agric Mach 53(1): 92-103.

- Huang Y, Han D, Han Z, Huang J, Chen P, et al. (2021) Experiment on the influence of vibration on the seeding performance of the scoop-wheel seed meter. J Henan Agric Univ 55: 896-905.

- Zhu M (2021) Study on the Effect of Field Vibration on Sowing Quality of Potato Planter [Master’s Thesis], Northwest A & F University: Yangling; China.

- Yazgi A, Degirmencioglu A (2007) Optimisation of the seed spacing uniformity performance of a vacuum-type precision seeder using response surface methodology. Biosyst Eng 97(3): 347-356.

- Fang L, Cao C, Qin K, Ge J (2022) Design and experiment of wheel seed metering device with guide ring groove combining U-hole for Radix Peucedani. Trans Chin Soc Agric Mach 53(4): 21-32.

- Dun G, Yu C, Yang Y, Ye J, Du J, et al. (2019) Parameter simulation optimization and experiment of seed plate type hole for soybean breeding. Trans Chin Soc Agric Eng 35(19): 62-73.

- Lu Y, Lu Z, Lu Y, Zheng W, Liu Z, et al. (2019) Design and experiment of chain casting corn precision seeder. J Agric Mech Res 41: 145-149.

- Wang L, Zhou M, Zeng Q (1999) Study on storage characters of tea seed. J Tea Sci 19(1): 25-28.

- Wan Q, Bu k, Li Y, Jiao W (2012) Structure analysis of the large no-till seeder openers. J Agric Mech Res 34: 45-48.

- Zhang X (2007) Agricultural Machinery Design Manual. China Agricultural Science and Technology Press.

- Fang K, Li B, Wu H (2021) Practical techniques for off-site conservation and breeding of tea germplasm. Guangdong Tea 06: 20-22.

- Feng H, Gao N, Meng Z, Chen L, Li Y, et al. (2018) Design and experiment of deep fertilizer applicator based on autonomous navigation for precise row-following. Trans Chin Soc Agric Mach 49(4): 60-67.

- Zhang J, Song W, Cao Y, Wang C, Guo H, et al. (2022) Design and experimental study on key components of garlic seeder. J Agric Mech Res 44: 129-136.

- Jia G (2021) Design and Experiment of Chain-Spoon Type Ginseng Precision Seeder [Master’s Thesis]. Kunming University of Science and Technology.

- Zhang H (2022) Structural Design and Experimental Research of a Double-Disc Trenching and Fertilizing and Mulching Machine for Tea Plantations [Master’s Thesis]. Fujian Agriculture and Forestry University.

- Meng Z (2002) Battery selection and data calculation. China Cable Telev 07: 70-71.

- (2005) Agricultural Industry Standard of the PR China. Single-Grain (Precision) Planter Test Method. China Agriculture Press GB_T 6973-2005.

- (2019) Agricultural Industry Standard of the PR China. Planter. China Agriculture Press DGT007-2019.

We use cookies to ensure you get the best experience on our website.

We use cookies to ensure you get the best experience on our website.