Review Article

Creative Commons, CC-BY

Creative Commons, CC-BY

Innovations in the Equipment of Municipal Wastewater Treatment Plants in Rural Settlements

*Corresponding author: Evgeny Pavlovich Sidorov, Deputy Director for Research and Technology, Agrostroyservis Research and Production Association, Dzerzhinsk, Russia.

Received: July 24, 2024; Published: July 30, 2024

DOI: 10.34297/AJBSR.2024.23.003081

Annotation

The article presents the results of a study by Scientists of the Federal State Statistics Service of Russia on the state of sewage systems for domestic wastewater in the territory of municipalities of different categories and population in the Russian Federation. It is noted that small settlement formations are not sufficiently provided with sewage systems for normal life. The author of the article offers several modern scientific and technical concepts of technological and design support for sewage systems of small settlement formations and detached buildings. In the construction of these structures, it is proposed to use technologies and equipment that provide savings in the consumed electric energy and material resources. For example: injection systems from Korting and Mazzei, as well as the construction of Franz Zotloterer’s mini-hydroelectric power plants, together with low-capacity wastewater treatment plants, which successfully operate on small reservoirs and deep streams, in order to provide structures with electric energy. It is presented, for potential investors, an innovative project of sewage treatment plants with a sewage treatment plant using the method of helical spiral implosion rotation of the water flow.

Keywords: Rosstat analysis, Sewer supply indicators, Settlement formations, Korting ejectors, Sponge, Mazzeiejectors, Exair air amplifiers, Ozonators, Water flow implosion

Just As the Theater Begins with A Hanger, So the Well-Being of Human Life Begins with The Cleaning of Drains

The main threat to the life of citizens of the Russian Federation in peacetime is the violation of the original ecological state of the environment. Including the safe state of the quality of State reserves of fresh water volumes. Russia ranks first in the world in terms of water resources availability. However, only 12% of water resources belong to clean water reserves. Since 58% are moderately polluted, 26% are dirty, and 4% are very dirty. Fresh water reserves amount to 97 thousand km33, but only about 11.6 km3 canbe used. The main reserves of fresh water are found in lakes and glaciers. And the resources of the rivers from which we take fresh water make up 0.5 % or 0.58 thousand km33. The total consumption of fresh water in Russia is 81.0 km33 per year, of which the housing and utilities sector consumes 15.6 km33 per year, including non-returnable consumption of 3.5 km33 per year. According to official sources, only 2.5 km3 of fully treated domestic wastewater is discharged into rivers in Russia3 per year, while the remaining amount is discharged contaminated. Scientists claim that every liter of untreated wastewater pollutes 8 liters of clean water in reservoirs. Therefore, the housing and utilities sector annually pollutes at least 100 km3of drinking water per year. That is, significantly more than the total consumption. In water bodies, based on the natural programming of the equilibrium state of sustainable life, a natural process of self- purification of water occurs. However, with the growth of the population and the lack of purification of used water, there may come a time for non-renewable processes of natural purification of reservoirs, which will lead to avalanche, explosive poisoning of them. According to an analysis conducted by Rosstat of Russia, in 2018, about 22.6% of the Russian population does not have access to centralized sewerage. Most of these families use cesspools.

Based on the analysis of the state of domestic wastewater treatment in residential settlements conducted by Rosstat of Russia, it follows that at present it is necessary to pay special attention to the design and construction of wastewater treatment facilities of average capacity, with a volume of 200 to 1000m3/day. However, the conditions of territorial location of settlement formations differ, in most cases, by insufficient energy supply and limited opportunities for discharging treated wastewater into nearby reservoirs, which are mainly small rivers and streams. It is also necessary to take into account the high biological contamination of wastewater due to the low degree of improvement of water drainage devices and hygienic equipment of residential facilities.

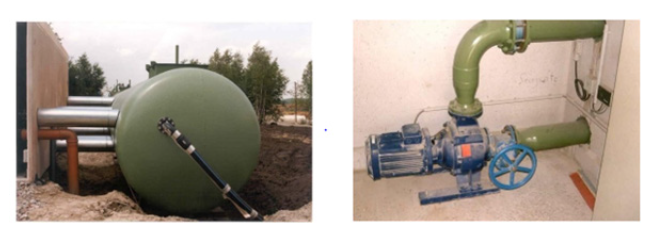

In order to solve this problem, the experience of the German company "Korting Hannover AG" on the use of cylindrical flow tanks with a length of up to 12.0 meters and a diameter of 2.0 meters, with a height of filling with a waste water flow equal to 1.6 meters, is interesting. Ejectors designed and manufactured by Korting are used as wastewater aeration equipment Korting. In terms of energy consumption, the most efficient way is to pre-compress the air to hydrostatic pressure and feed it to the suction side of the ejector. And then mixing the liquid with compressed air I n the ejector. In this case, it requires a lower working fluid pressure. At the same time, the amount of air in the liquid at the ejector outlet increases. The working nozzles of Korting ejectors are equipped with spiral nozzles to prevent clogging. In this way, the working fluid jet disperses the air at low pressure into countless small bubbles that mix with the working flow in the mixing zone. This air-water mixture is pumped into the aeration reactor in high turbulence mode. In this case, the water is saturated with excess oxygen. Oxygen transport depends not only on the size of the bubbles, but also on the renewal of the surface of the bubbles due to the turbulent flow of water. Under these conditions, the ejector guarantees optimal oxygen transfer and mixing of the entire volume of the aeration reactor. Even with a significant biomass content in the wastewater, it is possible to maintain a sufficient flow rate to prevent precipitation at the bottom of the reactor. Korting specialists conducted comprehensive tests of oxygen saturation in clean water (FNV M-209) using the oxygen adsorption method, which formed the basis for calculating Korting ejectors (Figures 1,2).

Ejectors Korting ejectorsare successfully used in cyclic-periodic reactors, in which, along with aeration processes, biological nitrification and denitrification processes are carried out in the same reactor, which requires complete mixing of the reactor contents both with and without air supply. This is achieved by simply shutting off the air valve during anaerobic wastewater treatment. A special advantage of this scheme is that the same pumps are used for all processes, which affects the overall cost of the installation, in terms of reducing it (Figures 3,4).

Figure 3: General view of a recumbent reactor assembled from 3 tanks (treated area in the reactor, with a diameter of 2 meters-36 x 1.6 m (filling height) “Korting”.

In wastewater treatment plants «Korting wastewater treatment plants, which use multi-pass ejector devices for aeration and mixing of wastewater, mainly use water- jet air compressors. Their installation is carried out outside in separate rooms, which requires additional construction space and capital expenditures (Figures 5,6).

It should be noted that the advantages of Korting ejectors are the absence of scheduled maintenance, since there are no moving parts in their design. And also, a high degree of oxygen saturation, since small bubbles form a large surface of contact between air and water, and high turbulence renews these surfaces; there is no precipitation, since the intense flow directed to the bottom of the reactor prevents the deposition of biomass; direct contact of oxygen supply is carried out. The design prevents clogging, since the diameter of the working nozzle determines the narrowest place in the cross-section; there is no problem of water overflow, since if the system is not active, water can rise into the air pipes without negative consequences. At startup, the ejector pumps all the liquid out of the pipes.

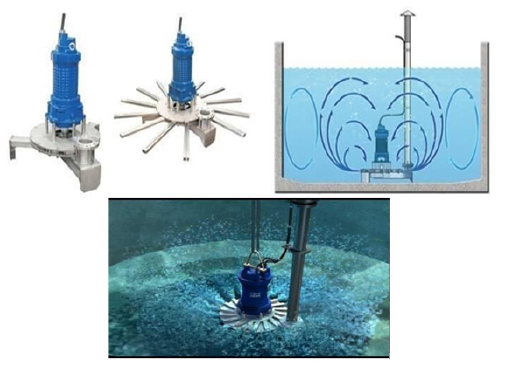

However, the use of water-jet air compressor pumps reduces the economic efficiency of the plant. Since wastewater aeration is an energy-intensive process and consumes 50-90% of the total power of the CBS, in recent years, in order to reduce the cost of forced air supply to the mixing chambers of ejectors by means of compressor equipment, almost all production and installation organizations in Western countries have begun to use submersible aerators. The design of submersible aerators consists of a submersible sewage pump, an air-liquid ejector and an air- sucking pipe. The device operates completely submerged in a liquid medium. For different stages of the wastewater treatment process (aeration, sediment mixing under aerobic and anaerobic conditions), the industry offers submersible aerators in various technical versions that can meet any conditions of the treated wastewater, in terms of reducing energy costs compared to traditional aeration systems. For example, along with Korting ejectors, you can note small bubble aerators Flymarator. The design of this aerator differs from others by the presence of an impeller that works in a clockwise direction, moving the surrounding liquid and increasing its speed. At the same time, a vacuum is created, which is filled with air drawn from the atmosphere through the air supply pipe. The air is thoroughly mixed with the liquid before being discharged through the diffuser channels at high speed, creating masses of fine bubbles and ensuring optimal oxygen retention time at high efficiency. The main thing is that you don't need compressors Aeration of the entire wastewater volume (Figures 7,8,9).

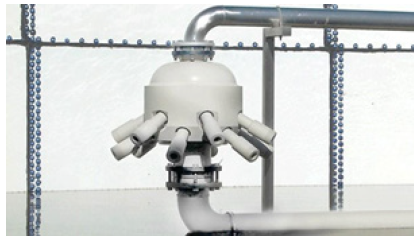

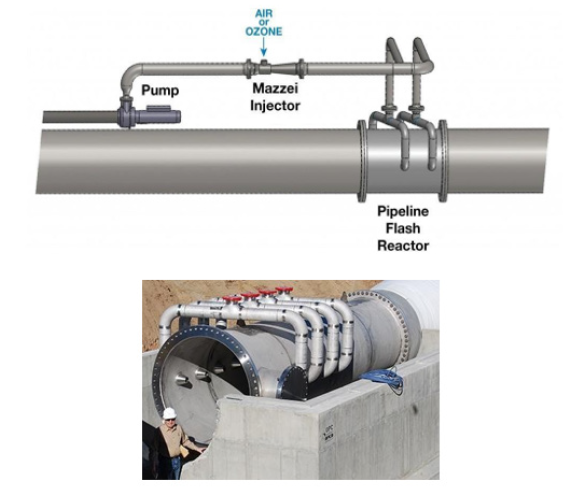

Special attention should be paid to the concept of MAZZEI specialists (USA) of methods for cleaning non-constant in time and average in volume of economic and fecal effluents of settlement formations. Aeration and saturation of effluents begins already during their transportation in pipelines by injecting air oxygen, ozone or oxygen, specially designed for this purpose, devices. This method allows you to pre-average the parameters of waste water for admission to the main wastewater treatment plants and significantly reduce their production load and, accordingly, operating energy indicators. At the same time, unpleasant odors of pipeline systems are removed. The insertion point of the aeration system is determined experimentally, if necessary (Figures 10,11).

The vast majority of air-liquid ejectors operate as a result of forced supply of compressed air to the zone of formation of the ejector mixture by compressor units of various capacities. For example, a Korting four-way ejector Korting requires about 88m3/ h of compressed air for a stable injection process, which corresponds to a blower capacity of 1.6m3 / min. At the same time, the oxygen supply level will be 14 kg O2/hour. However, it is possible to significantly reduce the energy and capital costs of providing the ejector with compressed air by using an EXAIR air pneumatic booster (USA) as a compressed air manufacturer. Using the Super Air Amplifier series as an example Air Amplifier, let's look at the schematic diagram and operation of the 120028 amplifier 120028 (see Figure 12). Compressed air with a volumetric flow rate of 3.396 SLRM, passes through the inlet (1) into the annular chamber (2). It is then compressed and passed through a small annular nozzle at high speed. The primary air flow adheres to the wall (Co and effect) and is sent to the outlet. A low-pressure area (5) is created in the center, which allows a large amount of ambient air to be drawn in. The combined flow from the ambient and primary air exits the air amplifier, creating a high-speed volumetric air flow, with a volumetric flow rate of 84,900 SLRMS at the output cross-section line of the amplifier and 254,700 SLRMS SLRM at a distance of 152 mm from this cross- section. Thus, using the Super Air Amplifier Amplifier, we achieve a certified volumetric air flow rate of 1.6 m3/ min, with an initial air flow rate of 25 times less than the blower capacity recommended by Korting for stable operation of the four-way ejector.

Figure 12: Schematic diagram of the operation of the air pneumatic amplifier series Super Air Amplifier.

It should be noted that the EXAIR air flow booster EXAIR performs various functions, the main ones are ventilation, purging and cleaning of pipeline systems. The main advantages of the air booster design are: no moving parts. This ensures its durability, unpretentiousness and ease of maintenance. Supply it with clean and dry air, and it will run almost indefinitely, without the need for maintenance.

The design of the air flow booster is protected by a US patent

US 4046492A, date Priority Date: 1976-01-21 (Figures 12,13,14,15,16).

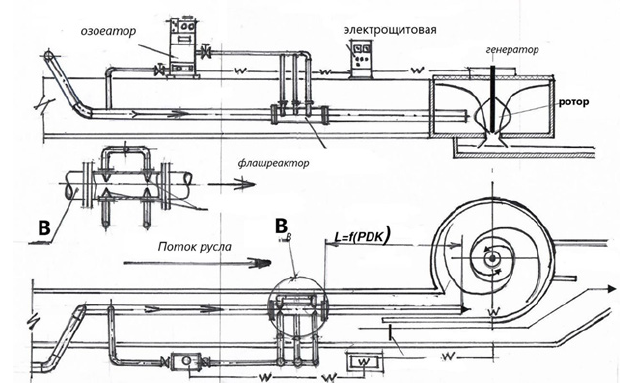

For the construction of wastewater treatment plants for small settlements, the project of additional treatment and discharge of treated wastewater into small rivers and streams through a water vortex mini-hydroelectric power station designed by the Austrian engineer Franz Zotloterer is of interest. Pretreatment of effluents at biological treatment plants that use various methods of anaerobic and aerobic water treatment requires additional post-treatment of chemical compounds related to the maximum permissible standards of fisheries waters. To solve this problem, it is proposed to connect ozonation equipment and a water power plant at the site of discharge of treated water into shallow reservoirs, which will simultaneously meet the installation's electricity needs (Figures 17).

Figure 17: Post-treatment plant for domestic wastewater that has been pre-treated at biological treatment plants by ozonation up to the maximum permissible discharge rate in fisheries reservoirs at Wasserwirbeltechnik Franz Zotloterer.

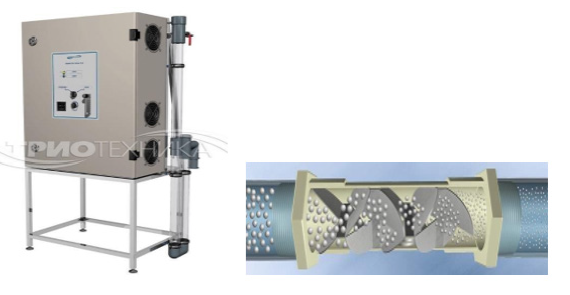

Post-treatment plant for domestic wastewater that has been pre-treated at biological treatment plants by ozonation up to the maximum permissible discharge rate in fisheries reservoirs at Wasserwirbeltechnik Franz Zotloterer. The project combines the equipment of the F. Zotloterer mini-hydroelectric. power station (Figures 18,19) and a Mazzei ozonator with a flachreaktor mixing system flachreaktor.

The project of this gravity-water circulation station makes it possible to generate electricity on small channels and rivers, as well as even on full-flowing streams, without blocking the river with a dam and thereby creating a free passage of fish. The whirlpool aerates the water, thereby restoring the cleaning processes of the riverbed. In addition, it contributes to the thermoregulation of the reservoir in summer, and in winter the mini-hydroelectric power station continues to work already under the ice. The diameter of the pool with a water rotation is 5.5 meters, which gives part of the flow near the shore to a special channel - this is a concrete cylinder, to which the water approaches tangentially, collapsing into the depth in the very center. So a whirlpool is formed, with the help of which the turbine is twisted. The efficiency of converted energy to current from falling water reaches 75%. The electrical power of the unit reaches 9.5 kW. The working height difference of the water is 1.3 m, and the flow rate is approximately 1m3 per second. The turbine showed good efficiency even with a water drop of 0.7-0.9 m. The gravity turn station generated more than 50 MWh of electricity on a small stream.

The use of ozonation of pre-treated wastewater is particularly appropriate for the combined solution of several complex tasks, namely, the removal of chemical compounds that are particularly sticky in solutions, disinfection and disinfection. To solve cleaning problems in small wastewater treatment plants, it is advisable to use ozonators that produce an ozone-oxygen mixture with a concentration of 2.5 to 20.0% ozone. For such low doses of ozone, direct ozone injection is most appropriate without cycling the water flow. Therefore, in the presented pretreatment of wastewater, a direct introduction of an ozonated mass of pre-treated wastewater is used directly into the flash reactor, where ozone-saturated water MAZZEIis intensively mixed with the flow by special MAZZEI ejection nozzles (Figures 20,21).

The presented installation for post-treatment of domestic wastewater that has passed the first stage of treatment using ozonation to the maximum permissible discharge rate to water bodies for agricultural purposes through a gravity-rotating station designed by Frank Zotleterer has a number of environmental, energy and economic advantages over existing prototypes.

The world's leading companies that have developed and implemented scientific and technological progress in the field of water solutions treatment, including domestic wastewater treatment, by intensifying the processes of injecting air oxygen or ozone and pure oxygen into an aqueous solution, are the companies “Mazzei", "Koоrting Hannover AG" and some companies Japan and other countries that use this method as an auxiliary one. However, the transformation of compounds is carried out by introducing air oxygen or ozone and pure oxygen into the body of an aqueous solution, on the surface of molecules, and not by initiating the internal action of internal water forces. Currently, a wastewater treatment plant is proposed by using the internal energy of water extracted from the energy- mass of water, in a non-explosive way at the intramolecular and intraatomic energy levels, by implosion screwing the water flow to its central axis through a quantum- wave coherent waveguide node, while inducing centripetal and centrifugal rotation of the water flow. The forces of these rotations, together with the forces of magnetic field resonances, create a resonance of the vibration frequencies of elementary particles that make up the structure of the water molecule, which leads to the destruction of their bonds and, accordingly, to the disintegration of the energy-mass of the aqueous solution into individual chemical elements and particles. As a result of such processes, the compounds break down and live, in the future, according to their strictly individual program, and the aqueous solution is purified from the chemical elements dissolved in it and regains its original quality. All processes occur in a time interval of 10-10-10 seconds.

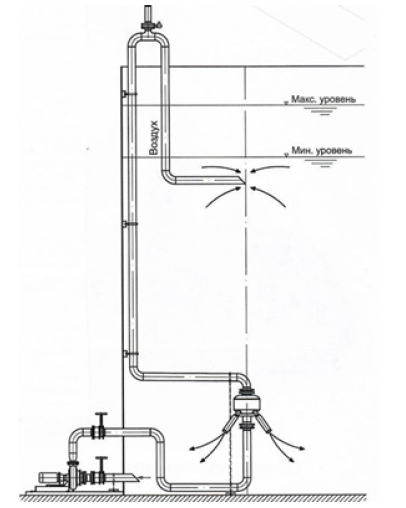

The construction of domestic wastewater treatment by the method of helical spiral implosion rotation of the water flow consists of underground and aboveground parts. The underground part is a monolithic concrete tank with a diameter of 6 meters and a height of 6 meters, in which there is an averager of wastewater coming from the main sewer system and a sewage pumping station (КНС), equipped with three submersible pumps.

The facility is designed for wastewater treatment of a separate residential complex of buildings with a population of 10,000 people. According to the author's ecological calculations, it can be tied in the general plan, in the middle of the green zone of a residential block, surrounded by a small reservoir, into which purified, decontaminated and disinfected water will be discharged. Excess water entering the reservoir is discharged into the external collector.

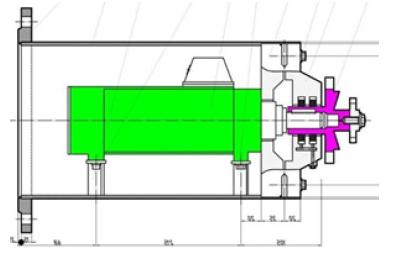

Above the underground part is a collapsible building made of metal structures, which has a circular shape in plan and a spherical roof covering. The building is equipped with an installation for cleaning domestic wastewater by the method of helical spiral implosion rotation of the water flow (UOS) (Figure 22).

The UOS consists of a metal tank with a diameter of 3 meters and a height of 3 meters, with a hatch with a diameter of 500 mm for servicing equipment that is located inside the tank, as well as a drain pipe. Reaction pipelines are installed inside the tank, which contain electric motors with devices for swirling the water flow. As well as a water flow converter with inlet and outlet chambers. Above the water flow discharge chamber, a chamber for stabilizing the discharge of purified water is installed, which is equipped with a pontoon-type level and a pulse safety valve. The valve is designed to normalize the pressure of air and exhaust gases formed during reactions.

Averaged sewage flows from the CNS to the reaction tank of the UOS by means of Korting ejectors, which are designed for installation through the wall. At the time of preparation of the UOS for start-up, waste water enters the reaction pipelines according to the law of communicating vessels to the level of full filling. After filling, the level sensors located on the inner part of the tank walls are triggered and the water supply stops. (Figure 23).

At the same time, electric motors are turned on, which, by means of swirlers, cause water to implosion rotation and axial linear movement. Simultaneously with switching on the electric motors, the CNS pumps are switched on. The process of setting the installation to operating mode begins. At this time, the treated water flows from the discharge chamber, through the bypass pipeline, go back to the average. An automatic computer system for determining the quality of treatment

indicators supports this process to the planned level of quality of treated water. When the required parameters are reached, the discharge of clean water is transferred to the operating mode, to the pool of clean water. Cleaning technology, due to the complete disintegration of biological elements, allows not only to disinfect but also to disinfect treated wastewater (Figures 24,25) [1-5].

Each wastewater treatment method has its own aspects of improving efficiency and reducing energy and economic costs. Their combination is not only advisable, but also environmentally justified, since cleaning is often required to be carried out at local sites of construction of sewage treatment plants. The use of local complexes is cheaper than the use of monolithic reinforced concrete structures. Such installations require minimal energy costs for operation, as well as prompt installation and easy maintenance.

Acknowledgement

None.

Conflict of Interest

None.

References

- EP Sidorov (2023) Physical capabilities and design features of a wastewater treatment plant by jet implosion. UNIVERSUM: Technical Sciences.

- Ozone water purification and disinfection systems. Wastewater treatment.

- Wastewater. Ozone for Dizinfection. Ketrofit Ftration. Activated Sludge. Aeration.

- Korting Yfnnover GmbH. EJECTOR kompakt Korting.

- Manifakturing intelligent Compressed. Seide Presentations.

We use cookies to ensure you get the best experience on our website.

We use cookies to ensure you get the best experience on our website.