Review Article

Creative Commons, CC-BY

Creative Commons, CC-BY

Progress of Research on Gradient Hydrothermal Oil Recovery from Oily Sludge

*Corresponding author: Tao Yu, Shaanxi Oil and Gas Pollution Control and Reservoir Protection Key Laboratory, State Key Laboratory of Petroleum Pollution Control, College of Chemistry and Chemical Engineering, Xi’an Shiyou University, China.

Received: August 09, 2024; Published: August 15, 2024

DOI: 10.34297/AJBSR.2024.23.003119

Abstract

The oily sludge belongs to hazardous wastes, which is difficult to degrade and harmful to the environment and human body, furthermore, it is one of the research focuses of scholars at home and abroad. At present, the traditional treatment methods have problems such as large residue, incomplete treatment, and easy formation of secondary pollution. In contrast, hydrothermal technology is an efficient and promising harmless treatment technology for hazardous wastes, which will further promote the harmless treatment of oily sludge. This paper reviews the research status of oily sludge treatment at home and abroad, the research progress of oily sludge hydrothermal oxidation treatment technology, the influencing factors of oily sludge gradient hydrothermal oil recovery technology and process, and the mechanism of petroleum compounds conversion in sub/supercritical water, in order to better provide reference for the gradient hydrothermal recovery of oily sludge.

Keywords: Oily sludge, Hydrothermal oxidation technology, Oily sludge treatment

Introduction

Oily sludge is generated during all processes in the petroleum industry, and in particular, during petroleum exploitation, storage, transportation, and refining. These include bottom sludge from tank cleaning, sludge produced by oily wastewater treatment stations, and deposited sludge collectively referred to as oil-containing sludge. The composition and properties of the sludge are affected by many factors, among which the geological type, soil composition and storage conditions of the oil region are the most critical factors. Oily sludges from different sources exhibit distinct characteristics such as high viscosity, toxicity, acidity; they represent highly stable three-phase mixed systems consisting of Water-in-Oil (W/O) or Oil-in-Water (O/W) emulsions. Traditional methods for disposal and treatment of oily sludges like landfilling, incineration curing, and biodegradation suffer from drawbacks including low efficiency, costliness, waste generation, and environmental pollution risks. Each of these methods has its own advantages in terms of reduction and resource utilization, but still lacks in terms of harmlessness. Therefore, there is an urgent need to develop safe and efficient oil sludge harmless treatment technology to solve this problem. However, the research and application of hydrothermal oxidation technology in sludge treatment has opened up a new way for sludge management and disposal [1].

Hydrothermal technology is an efficient and promising method for the environmentally sound treatment of hazardous wastes. Hydrothermal oxidation, also known as wet oxidation, was initially developed in the United States and has demonstrated its effectiveness in addressing challenges such as oil-containing sludge, high-concentration black liquor from papermaking, and recalcitrant organic wastewater. This relatively novel oxidation method involves conducting reactions under high-temperature (100-400℃) and high-pressure (2-30MPa) conditions to decompose organic matter into water, carbon dioxide, and other harmless byproducts, thereby effectively eliminating pollutants, as illustrated in (Figure 1) [2]. The hydrothermal treatment of oily sludge enables complete harmlessness, degradation of oil organic matter, and eradication of all pathogenic bacteria present. Additionally, it facilitates the recovery of oil from the sludge while ensuring that the treated water and residue undergo further treatment or resource utilization. Thus, this approach achieves the "triple" treatment objective encompassing reduction, harmlessness, and resource utilization of oily sludge (Figure 1).

Revised sentence: This paper presents a comprehensive overview of the technology and process for gradient hydrothermal oil recovery from oil-containing sludge, based on extensive research in hydrothermal oxidation. The proposed method is characterized by its simplicity, cost-effectiveness, and ability to meet industrial discharge requirements while enhancing the utilization rate of oil-containing sludge. Moreover, it demonstrates remarkable adaptability to extreme conditions such as high gum and asphaltene content, emulsification degree, oil concentration, water scarcity, low solid phase presence, salt concentration, fouling propensity, and corrosiveness. Consequently, this approach holds significant potential for realizing the resource utilization of sludge.

Current Status of Research on Treatment of Oily Sludge

Source of Oily Sludge

The exploration, production, transportation, and refining of oil and gas fields result in the generation of a significant amount of oil-containing sludge. This includes the bottom sludge from clean tanks, the sludge produced by oil-containing wastewater treatment stations, and the deposited oil sludge. Collectively, these are referred to as oil-containing sludge.

The composition and characteristics of oil-containing sludge are influenced by various factors, with the geological type of the oil field area, soil composition, storage conditions, and different production processes being the most significant ones. This sludge exhibits high viscosity, toxicity, and acidity, forming a highly stable three-phase mixed system consisting of water-in-oil (W/O) or oil-in-water (O/W). It contains benzene, pyrene, phenol, anthracene as well as other polluting toxic substances along with a substantial amount of residual oil. Additionally, it harbors numerous pathogenic bacteria and parasites along with heavy metals such as chromium, copper, lead; salts; dioxins; Polychlorinated Biphenyls (PCBs); radioactive elements; and other difficult-to-treat toxic and hazardous substances. The absorption of these pollutants by plants and animals can gradually accumulate in the human body through the food chain leading to severe harm to human health [3].

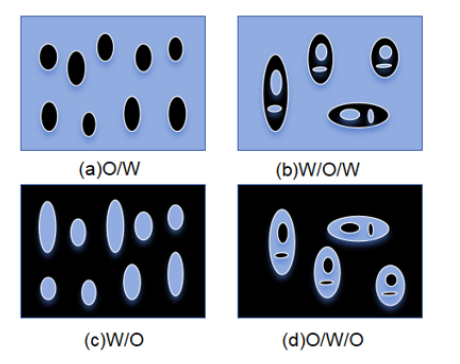

As shown in (Figure 2) oil-in-water (O/W) emulsions are produced by molecules with higher hydrophilicity, while water-in-oil (W/O) emulsions are produced in the presence of hydrophobic molecules. In unconventional waterflood oil recovery and production fluid transportation, the common emulsion is O/W type. W/O type emulsions are most commonly encountered in heavy oil transportation, asphalt foam treatment and pre-refining desalination, in which asphaltenes, waxes, resins, solids, naphthenes, aliphatic and aromatic acids act as natural emulsifiers to form films that stabilize dispersed phase droplets and prevent their coalescence. Complex emulsions in a broad sense include O/W emulsions and W/O emulsions, complex emulsions W/O/W /O emulsions and O/W/O emulsions, which are difficult to handle in petroleum production. Among them, the aging oil treated at the end of the offshore platform and the emulsified oil with a high degree of emulsification are common, and the complex emulsion in the narrow sense is complex emulsion. In terms of structure, the composite emulsion has a unique "two-film three-phase" multi-compartment structure, which is a highly dispersed and heterogeneous particle size polyphase system. W/O/W type emulsion is a common emulsion system at present.

The dispersing phase itself is water-in-oil (W/O) emulsion, and the inner water phase W1 and the outer water phase W2 are easy to dissolve because of the same polarity. O/W/O emulsion is a composite structure emulsion formed by dispersing droplets of O/W emulsion dispersed in the outer oil phase. It is a system in which both outer and inner phases are oils. Due to the existence of dual interface films of O/W and W/O, the system can be divided into three non-soluble regions (oil phase/water phase/oil phase), so as to achieve the coating and slow release of oil-soluble active ingredients. Make the system more stable. Generally, the demulsification mechanism of W/O/W system is mainly studied from the perspective of spatial repulsion and double electric layer interaction, while the O/W/O system mainly starts from macromolecular polymers to replace surface-active components in the interfacial rigid film. In the actual production of ASP, W/O, O/W, O/W/O emulsions coexist and have a stable emulsion state (Figure 2).

According to statistics, the annual discharge of oily sludge from petroleum enterprises in China has reached a staggering 3 million tons. Oily sludge is known to contain heavy metals, benzene, polycyclic aromatic hydrocarbons, and various other toxic substances. If not properly managed, these pollutants can pose significant threats to the environment and thereby endanger human health and safety [4-7]. The inclusion of oily sludge in the category of oily waste in the National Catalog of Hazardous Wastes, along with the requirement for environmentally sound treatment stated in both the National Cleaner Production Promotion Law and the Solid Waste Environmental Pollution Prevention and Control Law, demonstrates China's commitment to addressing this issue effectively.

Composition of Oily Sludge

Oily sludge is easy to form in the process of treatment due to long-term storage and pharmaceutical addition, and the emulsion becomes difficult to deal with. The following figure shows the formation structure of the emulsion (Figure 3).

Based on the study of emulsion chemistry and oily sludge used in this experiment, three mechanisms were proposed to stabilize the emulsification of oily sludge: (1) Due to the addition of various polymer surfactants in the process of oil extraction, the emulsion became stable and difficult to separate; (2) The stability of the emulsion due to the large amount of various anions in the water; (3) Stability of the emulsion due to the presence of natural emulsifiers such as asphaltenes, foreign polymers and the aggregation of granular colloids. Therefore, the main strategy of demulsification is to decompose the interfacial membrane material and structure of water and oil. As shown in (Figure 1), the oil-water transition layer contains an interface film between water and oil and various substances that lead to emulsification of oil-water emulsion, such as solid particle emulsifier, natural emulsifier and high polymer, which are all important factors in emulsification (Figure 3).

The composition of highly emulsified oil slush is extremely complex due to the variety of sources, and different sources of highly emulsified oil slush are not the same, and the formation of highly emulsified oil slush is closely related to the composition: On the one hand, the extensive application of oilfield chemicals in tertiary oil recovery makes the high emulsified oil sludge with polymers, alkali, surfactants and natural surface active substances such as colloid, asphaltene interaction, high emulsified oil sludge emulsification degree improved. On the other hand, the highly emulsified oil mud also contains conventional materials such as clay, sediment, mechanical impurities, suspended matter, sulfide and metal oxide micelles. Under the joint action of suspended matter and solid particles, metal oxides and sulfide micelles, the stability of the highly emulsified oil mud is further strengthened. The disposal of oily sludge in this state becomes particularly difficult (Table 1).

Oily Sludge Treatment Technology

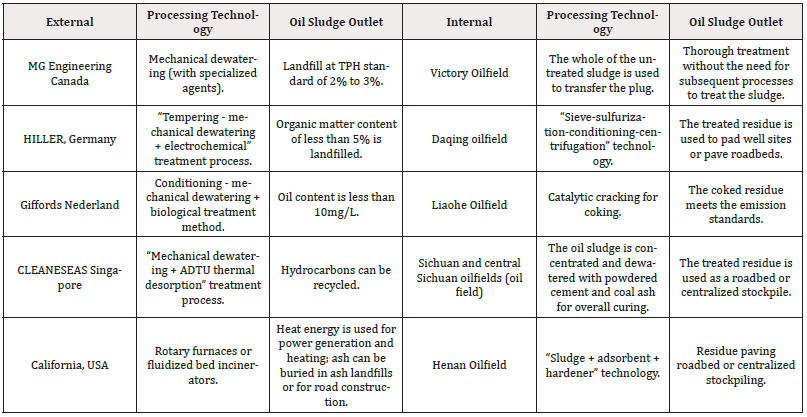

Most of China's oilfields have reached the intermediate and advanced stages of development, with the combined water content in the effluent exceeding 85%. The effluent contains a substantial amount of solid particles, resulting in an increased accumulation of oil-containing sludge during the production process. The National List of Hazardous Wastes (2016) includes "oil sludge and oil feet generated during oil extraction and refining processes"[8]. The implementation of an environmental protection tax in 2018 has led to changes in the treatment of domestic and foreign oil-contaminated soil, as indicated in (Table 1).

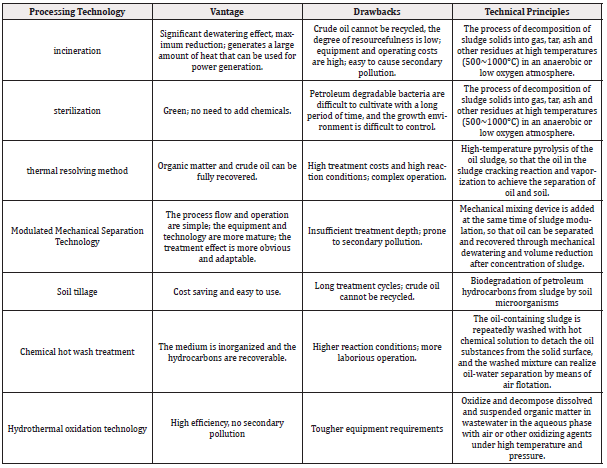

By analyzing the current soil treatment technologies employed by domestic and international oil companies, it becomes evident that reduction technology has reached a state of maturity. Furthermore, environmental protection agencies in certain regions have widely adopted and promoted serialized equipment to achieve the objectives of reduction, resource utilization, and harmlessness. The composition of different types of oil-containing sludge varies significantly, with the oil content primarily ranging from 5% to 60%. It contains hazardous substances such as benzene and PAHs, which are classified as HW08 hazardous wastes [13]. Currently, various treatment technologies have been developed based on the principles of reduction, resource utilization, and harmlessness for the traditional disposal of oil-containing sludge. These include incineration, bacterial injection method, thermal analysis method, and other common treatment technologies with their respective advantages and disadvantages outlined in (Table 2).

Development of Hydrothermal Oxidation Technology

Characteristics of Hydrothermal Oxidation Technology

Hydrothermal Oxidation (HTO) technology is a novel chemical oxidation technique. Since the 1970s, researchers have incorporated appropriate catalysts into the conventional Wet Oxidation (WAO) method to facilitate the completion of reactions under milder conditions (lower temperature and pressure), reduce reaction time, enhance oxidative decomposition, mitigate equipment corrosion, and minimize costs. Extensive research has demonstrated that HTO can effectively convert organic matter into harmless end products such as H2O and CO2. Carbon undergoes complete oxidation to CO2 [18]. The heteroatoms undergo transformation into inorganic compounds, with nitrogen being oxidized to N2 or NH3, phosphorus converted into phosphates, and sulfur converted into sulfates. Additionally, higher reaction temperatures lead to enhanced degrees of oxidation [19]. Given that the reaction temperature is significantly lower than the incineration temperature, the formation of NOx and other pollutants will be prevented, ensuring the absence of secondary pollution. This technology exhibits great promise for the oxidative disposal of oily sludge.

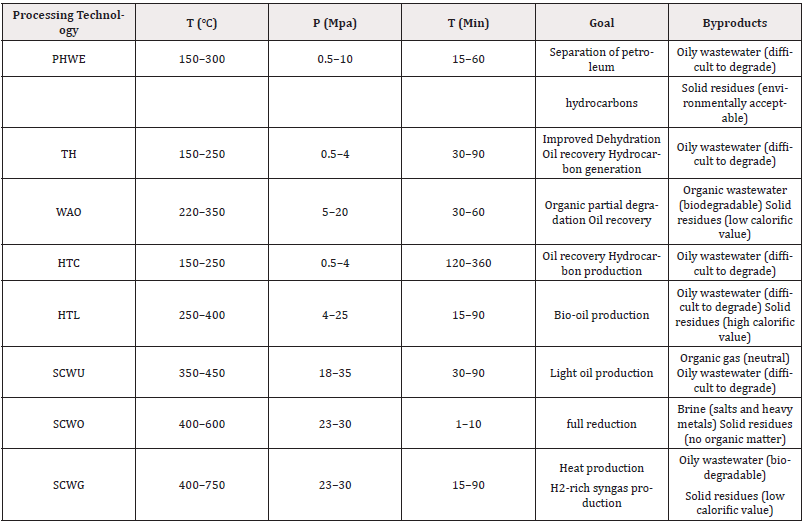

Hydrothermal treatment technologies for oily sludge encompass Pressurized Hot Water Extraction (PHWE), Thermal Hydrolysis (TH), Wet Oxidation (WAO), Hydrothermal Carbonization (HTC), Hydrothermal Liquefaction (HTL), Supercritical Water Upgrading (SCWU), Supercritical Water Oxidation (SCWO) and Supercritical Water Gasification (SCWG). These technologies are employed to recover fuels such as charcoal, coke, oil, and H2-rich syngas, as well as to eliminate polluting or mineralizing organic contaminants. Consequently, by adjusting the operating parameters including temperature(T), pressure(P), residence time(T), oxidation coefficient (OC) and catalyst [20], multiple objectives of volume reduction, fuel recovery, and non-hazardous treatment can be accomplished. Different hydrothermal oxidation technologies exhibit distinct characteristics Table 3 summarizes the aforementioned hydrothermal technologies” (Table 3).

Table 3: Comparison of different hydrothermal oxidation technologies for the treatment of oily sludge [21-25].

Main Factors Affecting Hydrothermal Oxidation Technology

Reaction Temperature: The oily sludge gradient hydrothermal oil recovery technology primarily relies on the continuous enhancement of temperature and gradual oil recovery. Hydrothermal oxidation is conducted at temperatures ranging from 80 to 150℃ for the pyrolysis of light components, followed by emulsion treatment and subsequent oil-water separation for efficient oil recovery. Subsequently, under subcritical conditions, heavy components undergo hydrothermal oxidation for further pyrolysis, while difficult-to-degrade groups are subjected to hydrothermal oxidation under supercritical conditions to achieve enhanced degradation. Finally, the residue obtained after pyrolysis is recycled.

Under subcritical conditions, the heavy components were subjected to hydrothermal oxidation pyrolysis again, and the refractory groups were subjected to hydrothermal oxidation further pyrolysis under supercritical conditions, and the residue after pyrolysis was recycled. During the reaction process, the increase of the reaction temperature will promote the increase of the number of activation energy molecules in the reaction system as well as the increase of the solubility of water, thus improving the reaction efficiency. Cui Baochen [26] used supercritical water oxidation treatment to treat the bottom sludge of crude oil storage tanks artificially removed from the second oil extraction plant of Daqing Oilfield, and studied the effect of reaction temperature (390-450℃) on the oxidation effect with COD as an indicator, and concluded that the COD removal rate of the oil-containing sludge in the water increased with the increase of the temperature at a reaction pressure of 25 MPa and a peroxide level of 427%. Jing Guolin, et al. [27]. treated oil-containing sludge using supercritical water oxidation technology and studied the effect of reaction temperature (370-440℃) on the oxidation effect using COD as an indicator, concluding that the rate of crude oil degreasing increased with the increase of temperature and retention time, and the optimum was obtained when the reaction pressure was 24 MPa, a 10-minute retention time was used, and a reaction temperature of 440℃. Jude A, et al. [28]. used hydrothermal oxidation to treat oily sludge from a wastewater treatment plant in the United Kingdom, and the effects of reaction temperature (350-450℃) and pressure (24-34MPa) on the oxidizing effect were investigated using TOC as an indicator, and it was concluded that the removal rate of TOC from the oil-containing sludge tended to increase with both temperature and pressure, and the higher the temperature and pressure, the TOC removal rate was greater, and the oxidation effect was most obvious when the pressure was 34 MPa and the temperature was 450℃.

During the reaction process, the increase of the reaction temperature will promote the increase of the number of activation energy molecules in the reaction system as well as the increase of the solubility of water, thus improving the reaction efficiency [29]. The higher the temperature, the higher the COD removal rate of oily sludge. This is due to the increased chances of collision between hydroxyl radicals and organic matter when the temperature is increased, and the reaction rate is therefore increased [30].

Peroxide Ratio: With the gradual increase of peroxide ratio, the output water samples gradually clear, and COD gradually reduced, COD removal rate and oil removal rate are gradually increased; but as the peroxide ratio continues to increase, the number of COD and oil content is always maintained at a certain value is no longer a significant reduction in the COD degradation rate and the oil removal rate is no longer a significant change. Comparison of when the temperature, oxygen peroxide ratio and reaction time is constant, solid-liquid ratio, the higher the oil removal rate and COD removal rate gradually increased, but when the solid-liquid ratio increased to a certain extent, if you continue to increase the solid-liquid ratio, although it will not make the oil removal rate and COD degradation rate decreased, but the trend of increasing obviously slowed down.

From the effect of solid-liquid ratio ( initial oil content ) on the oil removal rate and COD removal rate of oily sludge, it can be seen that with the increase of the gradient of solid-liquid ratio ( initial oil content ), the degradation of oil and COD in oily sludge also increases, which can provide a basis for the experiment of hydrothermal oxidation technology of oily sludge gradient (solid-liquid ratio ( initial oil content). The results of many studies [30-32] showed that the COD removal rate increased significantly when the peroxide ratio was 3.0, and remained almost constant with the increase of peroxide when the peroxide ratio was above 3.0. This indicates that when the peroxide ratio is above 3.0, the number of reaction stages of the oxidant in the reaction rate equation is 0. Increasing the amount of oxidant also improves the degradation effect, and when the oxidant is overdosed to a certain extent, then increasing the amount of oxidant has very little effect on the improvement of the conversion rate of the organic matter, and the increase in the amount of oxidant will increase the energy consumption of the compressor or the high-pressure pump, which also results in the wastage of the oxidant.

Reaction Mechanism of Hydrothermal Oxidation Technology

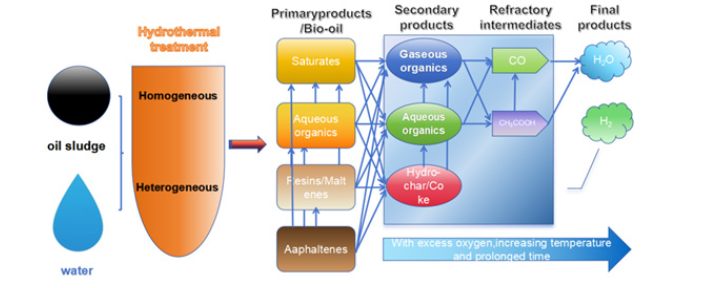

General Reaction Pathways of Oily Sludge in Sub/Supercritical Water: Oily sludge sub/supercritical water treatment products can be divided into four categories: gas, oil, liquid and solid. The chemical composition of petroleum hydrocarbons in oil-containing sludge is complex, containing a variety of organic compounds, which can generally be divided into saturated hydrocarbons, aromatic hydrocarbons, resinous hydrocarbons and asphaltenes (SARA) four components. SARA analysis is a common method to characterize thick oil. In addition, oily sludge contains small amounts of water-soluble organic matter and fixed organic carbon, which originate from the phase behavior of organic pollutants in sub/supercritical water significantly affecting their chemical reactions [33]. The water solubility of small molecules of organic matter increases with increasing concentration using window autoclave visualization to observe the SCW-bitumen interface [34]. It was determined that under sub/supercritical conditions, the oily sludge water system consists of an upper water-rich phase (homogeneous) and a lower oil-rich phase (non-homogeneous) as shown in (Figure 1).

Conversion of Petroleum Compounds in Sub/Supercritical Water

1) Hydrogen Production from Hydrocarbon Supercritical Water Reaction Hydrogen: Production from hydrocarbons was carried out by steam reforming and Supercritical Water Partial Oxidation (SWPO) under SCW conditions. Taylor, et al [35]. injected diesel fuel and water together into a reactor and then heated it up to 700℃ and 27.6MPa. Diesel and supercritical water undergo steam reforming reaction to produce hydrogen, but the oil and water phases cannot be mixed uniformly in the reactor, and a large amount of coke generated by the reaction clogged the reactor. Watanabe, et al. [36]. partially oxidized n-hexadecane (n-C16) to produce hydrogen in a SCW at 400℃, and the main products were H2, CO, CO2, C1 to C4, and oxygen-containing organic compounds. Watanabe, et al. [37]. further found that the addition of catalysts ZrO2 and NaOH, respectively, to the reaction system was able to promote the partial oxidation of n-C16, favoring the decomposition of major intermediate products such as aldehydes and ketones. For CO, the yields of H2 were 2 and 4 times higher than those without catalyst under the same conditions, respectively. García Jarana, et al [38]. obtained 0.19 mol H2/ (mol initial COD) using metal cutting oil waste fluid in SCW with oxygen content of 0% to 20%, temperature of 50 to 550℃, and pressure of 25MPa.

2) Hydrocarbon supercritical water partial oxidation synthesis of oxygenated compounds

i) Alkane supercritical water partial oxidation synthesis of oxygenated compounds SWPO methane can synthesize methanol in one step, and the excess heat generated from the oxidation reaction can also be used to generate electricity [39]. Lee, et al [40]. studied SWPO of CH4 at 400-450℃, and the main products of the reaction were CO, CO2, CH3OH, and H2. In the range of 400-410℃, the CH3O selectivity was highest at CH4 conversions of 1% to 3%, and it was up to 35%. Sudhir, et al [41]. catalyzed SWPO methane using Cr2O3/A12O3 and MnO2/CeO in a continuous reactor in the range of 400 to 475℃.Controlling the reaction conditions gave selective access to methanol, formic acid, and other partially oxidized products. Richter, et al [42]. in the range of 350 to 420℃ and at 25 and 30MPa, have studied the partial oxidation reaction of cyclohexane in ultra (near) critical water. The main products were cyclohexene, cyclohexanol, cyclohexanone, 1-propanol, 1-butanol, 1-pentanol, short-chain carboxylic acids, methane, ethane, and unsaturated hydrocarbons (e.g., ethylene, propylene), CO and CO2. The total selectivity of cyclohexene, cyclohexanone and cyclohexanol can reach 30%.

ii) Synthesis of aromatic carboxylic acids by supercritical water partial oxidation of aromatics In recent years, it has been found that the synthesis of aromatic carboxylic acids by partial oxidation of aromatic hydrocarbons in supercritical water without the use of organic solvents is an environmentally friendly process by replacing the solvent of acetic acid used in the industrial production process with water, without the use of organic solvents. Hamley, et al [43]. partially oxidized terephthalene under supercritical water conditions of 400℃ and 25MPa, using MnBr2 as a catalyst, and oxygen supplied by H2O2, resulting in terephthalene, p-xylylene and p-phenylene. Terephthalic acid was found to be 95% selective for the product terephthalic acid, while the by-product was only benzoic acid. Dunn, et al [44,45]. investigated the partial oxidation reaction of terephthalic acid under supercritical water conditions and found that the decarboxylation of the generated terephthalic acid occurs when the reaction time is longer than 10 min, which leads to the decrease of the terephthalic acid yield. The highest terephthalic acid yield was higher than 80%. Hydrothermal technology provides a green route for oily sludge treatment. Dewatering is an indispensable pre-treatment step in conventional treatment technologies, whereas hydrothermal treatment does not require dewatering because the reaction medium is water. In addition, sub/supercritical water acts as both a solvent and a reactant, on which basis oily sludge can be effectively treated.

Application of Hydrothermal Oxidation Technology in Sludge Treatment

Lendormi, et al [46]. used a batch reactor and a continuous pilot and industrial plant for the treatment of sludge from municipal wastewater treatment, where the main products of oxidation were CO2, water, VFA (volatile fatty acids) and ammonia. The results showed that the treatment temperature had a significant effect on the treatment effect: 70% COD removal was achieved at 240℃with an oxidation time of 1 h, and greater than 80% COD removal was achieved at 300℃ without the addition of any catalyst. Zeng, et al [47] and others carried out catalytic wet oxidation of pharmaceutical sludge in a batch reactor using molecular sieves loaded with Cu/Ce catalysts and discussed the catalyst dosage, the catalyst dose and the oxidation time. The study discussed the effects of catalyst dose, temperature, time and oxygen pressure on the treatment effect. The results showed that 75% COD removal was achieved at 260℃, 60 min, initial oxygen pressure of 1.0 MPa, and 10g/L catalyst. The effects of reaction pressure, reaction temperature and oxidant addition on the treatment effect of oily wastewater in wet oxidation process were investigated [48]. The COD removal rate of oily wastewater was 81.5% at 305℃, 14MPa, oxidant addition of 200 mg/L, and a residence time of 9 min. Meanwhile, the Box-Behnken design was used to find that the reaction temperature, residence time, catalyst dosage, and oxidant dosage had a large impact on the COD removal rate, with the temperature having the greatest impact on the COD removal rate.

Lai, et al [49]. prepared a series of M3-Al-500 catalysts (M=Cu, Mn, Fe, Ni, Zn, and Co) by controlled calcination of layered double hydroxides and performed catalytic wet oxidation experiments for high concentration of phenol (2.1g/L) under mild conditions (120℃ and 1.0 MPa). Cu3-Al-500 was found to be the most active of the catalysts tested, and phenol was completely converted within 2 h. The results showed that Cu3-Al-500 was the most active catalyst for the wet oxidation of phenol. The characterization results indicated that the performance of the Cu-based catalysts could be attributed to the redox transformation of Cu2+/Cu+ and/or the formation of H2O2 in the reaction mixture. Also, the surface acidity of Cu3-Al-500 accelerates the degradation of phenol. Possible phenol degradation mechanisms for Cu-based catalysts are proposed.

Resource Recovery and Disposal for Staged Hydrothermal Treatment

Recovery of Oil

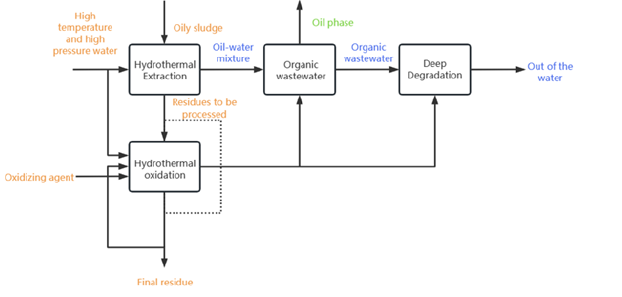

At present, the treatment of oily sludge mainly includes solvent extraction, composting, biodegradation, pyrolysis, incineration, etc. However, the existing treatment technologies have the disadvantages of unsatisfactory treatment effect, high treatment cost, secondary pollution, and unsuitable for large-scale industrial application [50,51]. The oil-containing sludge gradient hydrothermal catalytic oxidation treatment method, which belongs to the field of oil-containing sludge treatment technology, is simple and low-cost, which not only meets the requirements of industrial discharge, but also improves the utilization rate of resource utilization of oil-containing sludge and possesses the ability to cope with a multitude of extreme conditions, which is of extremely high value for production applications. Oil-water separation is carried out for the oil-containing sludge, and the separated residue is again processed by hydrothermal technology, and oil-water separation is carried out again, and the separated residue is again processed by hydrothermal technology, and separation is carried out again and again, i.e., graded separation is carried out, so as to achieve a better separation effect. The most critical is the use of hydrothermal oxidation technology to achieve the separation of oil, water, solid three-phase, in which the oil is recovered, realizing the recovery and recycling of resources. The following figure shows the process flow diagram of graded hydrothermal oil recovery (Figure 4).

Environmentally Sound Treatment of Residues and Wastewater

Oily sludge is a multi-phase system consisting of water, oil and mud (clay particles), etc. Oxidizing it in a supercritical environment can degrade complex toxic and harmful organic substances such as benzene and Polycyclic Aromatic Hydrocarbons (PAHs) contained in it, and completely oxidize and decompose them into non-toxic substances such as carbon dioxide and water. Due to the different sources and types of oil-containing sludge, the residue after gradient hydrothermal extraction will be directly discharged or used for resource reuse in accordance with the emission standards and requirements for resource reuse, and the optional resource utilization of the residue includes, but is not limited to, roadbed filler, building materials, and so on. If the non-oil organic matter (mainly asphalt) in the residue has no adverse effect on the resource utilization, and the resource utilization is not harmful to the environment, the residue that still contains a certain amount of non-oil organic matter does not need to undergo the secondary hydrothermal oxidation treatment, and can be directly utilized by resource utilization, such as for asphalt paving [52].

The discharged organic wastewater after the gradient hydrothermal extraction is the object of in-depth treatment, in which the organic matter is degraded into environmentally harmless small molecules, and the treated effluent treated effluent can at least reach the GB8978-1996 Comprehensive Wastewater Emission Standards, "the third level of discharge standards before discharge.

Conclusion

1) Hydrothermal technology provides a green route for oily sludge treatment. This paper reviews the research progress of oil-containing sludge gradient hydrothermal oil recovery, using water oxidation method to treat oil-containing sludge, detailed study of oil-containing sludge treatment research status quo, the development of hydrothermal oxidation technology characteristics and main influencing factors. The reaction mechanism of hydrothermal oxidation was discussed, and a gradient hydrothermal catalytic oxidation treatment method for oily sludge was provided. The oil-containing sludge gradient hydrothermal oil recovery technology is simple and low-cost, which not only meets the requirements of industrial discharge and improves the resource utilization rate of oil-containing sludge, but also has the ability to cope with the oil-containing sludge with high gelatin and asphalt content, high emulsification, high oil content, low water content, low solids content, high salt content, high scaling and corrosiveness, and so on, and it has a very high value of production and application.

2) The advantages of hydrothermal oxidation technology in treating oil-containing sludge are that it has high treatment efficiency, is pollution-free and can deal with difficult-to-degrade substances such as Polycyclic Aromatic Hydrocarbons (PAHs), consumes less energy than incineration, has no secondary pollution compared with pyrolysis and thermal washing, and is able to deal with difficult-to-degrade toxic and harmful substances compared with microbial methods, so hydrothermal oxidation treatment of oil-containing sludge has a better application prospect in the future. Based on the technology of hydrothermal oxidation treatment of oil-containing sludge, this paper aims to analyze the compositional changes of hydrothermal oxidation process of oil-containing sludge, and then discuss the feasibility of gradient hydrothermal oxidation technology and application of oil-containing sludge.

3) Hydrothermal oxidation technology has been used to treat oily sludge at home and abroad. The focus is on the harmless treatment of oily sludge. Gradient hydrothermal oxidation of oily sludge can realize the resource utilization of oily sludge and recover the oil. Therefore, gradient hydrothermal oxidation treatment of oily sludge has great development potential. It will be the focus of future research to make the treatment of oil-containing sludge realize minimization, resource utilization and harmlessness to the greatest extent, and to provide the theoretical basis for the further industrialization application.

Acknowledgement

None.

Conflict of Interest

None.

References

- Liu T L, Yu T, Gao G N (2021) Research progress of supercritical water oxidation technology[J]. Conference Series Earth and Environmental Science 804(4): 042009-042009.

- Liu Y, Bai F, Zhu C C (2013) Upgrading of residual oil in sub- and supercritical water: an experimental study. Fuel Process. Technol 106: 281-288.

- Khan M K, Cahyadi H S, Kim S M (2019) Efficient oil recovery from highly stable toxic oily sludge using supercritical water[J]. Fuel 235: 460-472.

- Wang Z, Gong Z, Wang Z (2020) Application and development of pyrolysis technology in petroleum oily sludge treatment[J]. Environmental Engineering Research 26(1).

- Ren S Y, Guan S, Shi J (2019) Current situation and suggestions of oil-containing sludge treatment at home and abroad[J]. Oil and Gas Field Environmental Protection 29(4): 4-7.

- Egazaryants SV, Vinokurov VA, Vutolkina AV (2015) Oil sludge treatment process[J]. Fuel and Oilseed Chemistry and Technology 51(5): 506-515.

- Du M, Li J, Wang F, Feifei Wang, Xiaokang Li, Tao Yu, et al., (2020) The sludge-based adsorbent from oily sludge and sawdust: preparation and optimization[J]. Environmental Technology 42(20): 3164-3177.

- Zhi Wei (2015) Research on the characteristics of oilfield oil-containing sludge and its sieving, fluidizing, tempering and centrifugal treatment efficiency[D]. Harbin.

- Gong W J, Ji Y, Ren Y L (2022) Research progress of hydrothermal oxidation treatment technology for municipal sludge[J]. Henan Science 40(06): 898-903.

- Martins D C C, Scandelai A P J, Lúcio Cardozo Filho (2020) Supercritical water oxidation treatment of humic acid as a model organic compound of landfill leachate[J]. The Canadian Journal of Chemical Engineering 98(4): 868-878.

- Qian L, Wang S, Xu D (2016) Treatment of municipal sewage sludge in supercritical water: A review[J]. Water Research 89118-89131.

- Ma D Z, Zhang L, Yin D (2011) Application of supercritical water oxidation technology in wastewater treatment [J]. Coal Technology 30(1): 202-204.

- Santos RM (2021) Recent advances in heterogeneous catalysis for supercritical water oxidation/gasification processes: insight into catalyst development[J]. Process Safety and Environmental Protection 149: 169-184.

- Kou J, Xu J, Jin H (2018) Evaluation of modified Ni/ZrO2 catalysts for hydrogen production by supercritical water gasification of oil-containing wastewater[J]. International Journal of Hydrogen Energy 43(30): 13896-13903.

- Chen Z, Tong K, He C (2021) High quality oil recovery from oil-based drill cuttings via catalytic upgrading in presence of near-/supercritical water and different industrial wastes[J]. Journal of Cleaner Production 321: 129061.

- Hochberg SY, Tansel B, Laha S (2022) Materials and energy recovery from oily sludges removed from crude oil storage tanks (tank bottoms): A review of technologies[J]. Journal of Environmental Management 305: 114428.

- Al Muntaser, Varfolomeev MA, Suwaid MA (2020) Hydrothermal upgrading of heavy oil in the presence of water at sub-critical, near-critical and supercritical conditions[J]. Journal of Petroleum Science and Engineering 184: 106592.

- Wu L (2017) Research and application of oil-bearing sludge treatment technology in Daqing oilfield [D]. Harbin Institute of Technology.

- Dou Y H (2020) Effect of hydrothermal method combined with advanced oxidation technology on the performance of sludge deep dewatering and its action mechanism[D]. Nanjing Normal University.

- Wang YS (2017) Research on treatment technology of oily sludge in the second oil extraction plant of Changqing oilfield[D]. Lanzhou:Lanzhou Jiaotong University.

- Chen Z, Tong K, Xu F (2021) Development of supercritical water oxidation technology for application to hazardous waste treatment: An extreme case study[J]. Journal of Environmental Chemical Engineering 9(4): 105296.

- Hu G, Li J, Zeng G (2013) Recent development in the treatment of oily sludge from petroleum industry: a review. Journal of hazardous materials 261: 470-490.

- Chen Z, Zheng Z, He C, Jumei Liu, Rui Zhang, et al., (2022) Oily sludge treatment in subcritical and supercritical water: A review[J]. Journal of Hazardous Materials 433: 128761.

- Chen Z, Tong K, He C (2021) High quality oil recovery from oil-based drill cuttings via catalytic upgrading in presence of near-/supercritical water and different industrial wastes[J]. Journal of Cleaner Production 321: 129061.

- Cui BC (2013) Research on supercritical water oxidation treatment of oily sludge[D]. Harbin Institute of Technology.

- Wang C, Zhu W, Zhang H, Cheng Chen, Xihui Fan, et al., (2019) Char and tar formation during hydrothermal gasification of dewatered sewage sludge in subcritical and supercritical water: Influence of reaction parameters and lumped reaction kinetics[J]. Waste Management 100: 57-65.

- Zhen L, Miao G, Mengqi W (2021) Influence of AlCl3 and oxidant catalysts on hydrogen production from the supercritical water gasification of dewatered sewage sludge and model compounds[J]. International Journal of Hydrogen Energy 46(61): 31262-31274.

- Zhang N, Wang YJ, Liu SJ (2021) Current status and progress of research on chemical hot washing technology of oily sludge[J]. Chemical Progress 40(03): 1276-1283.

- Yang JF, Zhang SY, Cao ZY (2022) Effect of hydrothermal oxidation pretreatment on the physicochemical properties of cotton stalk molding granules. Chemical Progress 41(08): 4417-4424.

- Zhang H, Zhang S, Weng Z, Mubeen I, Zhang C, et al. (2020) Alkali-catalyzed supercritical water gasification of sewage sludge: effect of liquid residue reuse as homogenous catalyst. International Journal of Environmental Science and Technology 17: 1-8.

- Onwudili J A, Radhakrishnan P, Williams PT (2013) Application of hydrothermal oxidation and alkaline hydrothermal gasification for the treatment of sewage sludge and pharmaceutical wastewaters. Environmental Technology 34(4): 529-537.

- Bonin J, Janik I, Janik D, David M Bartels (2007) Reaction of the hydroxyl radical with phenol in water up to supercritical conditions. Journal of Physical Chemistry A 111(10): 1869-1878.

- Feng HY, Zhou ZH, Hantoko D, Li Zhong, Dicka Ar Rahim (2021) Effect of alkali additives on desulfurization of syngas during supercritical water gasification of sewage sludge. Waste Management 131: 394-402.

- Yan M, Cui JT, Li T, Hongyu Feng, Dwi Hantoko, et al. (2023) Transformation and distribution of nitrogen and phosphorus in sewage sludge during supercritical water gasification. Fuel 332(P1).

- Wang CY, Zhu W, Fan XH (2021) Char derived from sewage sludge of hydrothermal carbonization and supercritical water gasification: comparison of the properties of two chars. Waste Management 123: 88-96.

- Chen WT, Haque MA, Lu T, Aersi Aierzhati, Gregory Reimonn (2020) A perspective on hydrothermal processing of sewage sludge. Current Opinion in Environmental Science & Health 14: 63-73.

- Wang L, Chang Y, Li A (2019) Hydrothermal carbonization for energy-efficient processing of sewage sludge: A review. Renewable and Sustainable Energy Reviews 108: 423-440.

- Xiuzheng Zhuang, Yanqin Huang, Yanpei Song, Hao Zhan, Xiuli Yin, et al. (2017) The transformation pathways of nitrogen in sewage sludge during hydrothermal treatment. Bioresource Technology 245: 463-470.

- Yan Shi, Gang Luo, Yue Rao, Huihui Chen, Shicheng Zhang (2019) Hydrothermal conversion of dewatered sewage sludge: Focusing on the transformation mechanism and recovery of phosphorus. Chemosphere 228: 619-628.

- Andres Sarrion, Angeles de la Rubia, Charles Coronella, Angel F Mohedano, Elena Diaz (2022) Acid-mediated hydrothermal treatment of sewage sludge for nutrient recovery. Science of the Total Environment 838: 156494.

- Chuan Peng, Yunbo Zhai, Yun Zhu, Bibo Xu, Tengfei Wang, et al. (2016) Production of char from sewage sludge employing hydrothermal carbonization: char properties, combustion behavior and thermal characteristics. Fuel 176: 110-118.

- Merzari F, Langone M, Andreottola G, Fiori L (2019) Methane production from process water of sewage sludge hydrothermal carbonization. A review. Valorising sludge through hydrothermal carbonization. Critical Reviews in Environmental Science and Technology 49(11): 947-988.

- Su Y, Liu D, Gong M, Wei Zhu, Yaqin Yu, et al. (2019) Investigation on the decomposition of chemical compositions during hydrothermal conversion of dewatered sewage sludge. International Journal of Hydrogen Energy 44(49): 26933-26942.

- Kong L, Liu S, Luo L, Wang Yuanyuan, Dai Liyi (2019) Enhanced methane yield from supercritical water gasification of pentadecanoic acid. Fuel Processing Technology 193: 48-52.

- Patricia Guerra, Azadeh Zaker, Pu Duan, Alex R Maag, Geoffrey A Tompsett, et al. (2020) Analysis of coke formed during zeolite-catalyzed supercritical dodecane cracking: Effect of supercritical water. Applied Catalysis A: General 590: 117330.

- Zhong Chen, Zhijian Zheng, Chunlan He, Jumei Liu, Rui Zhang, et al. (2022) Oily sludge treatment in subcritical and supercritical water: A review. Journal of Hazardous Materials 2022: 128761.

- You Han, Tengzhou Ma, Fang Chen, Wei Li, Jinli Zhang (2019) Supercritical water gasification of naphthalene over iron oxide catalyst: A Reax FF molecular dynamics study. International Journal of Hydrogen Energy 44(57): 30486-30498.

- Hochberg S Y, Tansel B, Laha S (2022) Materials and energy recovery from oily sludges removed from crude oil storage tanks (tank bottoms): A review of technologies. Journal of Environmental Management 305: 114428.

- Dang Z, Zhu X, Wang L, Guodong Ji (2021) Titanium dioxide catalytic hydrothermal liquefaction to treat oily sludge: As hydrogen production catalyst. Chemical Engineering Journal Advances 8: 100139.

- Hui K, Tang J, Lu H, Xi B, Qu C, et al. (2020) Status and prospect of oil recovery from oily sludge: A review. Arabian journal of chemistry 13(8): 6523-43.

- Onwudili J A, Williams PT. (2006) Flameless incineration of pyrene under sub-critical and supercritical water conditions. Fuel 85(1): 75-83.

- Reina TR, Yeletsky P, Bermúdez JM, P. Arcelus Arrillaga, VA Yakovlev, et al. (2016) Anthracene aquacracking using NiMo/SiO2 catalysts in supercritical water conditions. Fuel 182: 740-748.

We use cookies to ensure you get the best experience on our website.

We use cookies to ensure you get the best experience on our website.